vacuum transfer line.

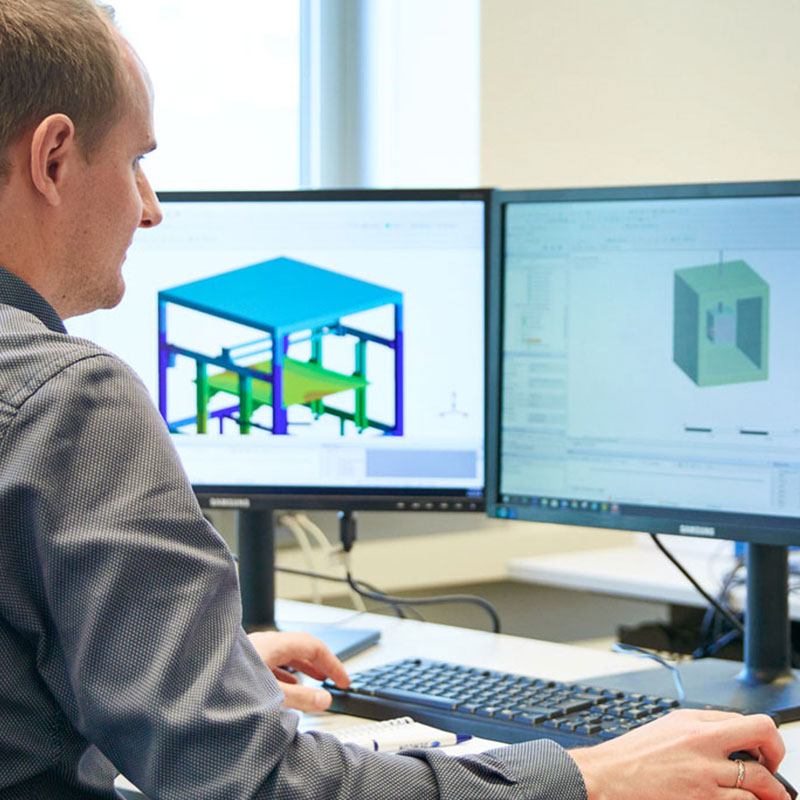

Researchers aiming to create new materials by depositing thin layers often would like to use multiple deposition techniques for this purpose. We have developed a vacuum transfer line to which they can connect different deposition devices. That gives them additional possibilities for developing ‘smart’ and energy-efficient materials.

regulation and lubrication.

The vacuum transfer line is modular and can be as long as ten meters, with connections for up to six systems. The transport tube contains an ultra-high vacuum with a base pressure of less than 10–9 mbar. The design of the regulation and lubrication mechanism for the transport system’s motorized drive presented a challenge during the line’s development. The line’s sophisticated regulation mechanism prevents any instability in pressure and vacuum from occurring due to movements. Due to the high bakeout temperatures required for the high-vacuum tube, a plastic material, such as Teflon, was not suitable as lubricant. This is why a molybdenum sulfide layer was applied as a dry lubricant.

"we are a systems integrator for thin film processes and measuring instruments."

We have increasingly more clients who would like to use different deposition techniques to make complex materials with different layers, in order to be able to develop new properties. With our transfer line we are responding to that need. Users can connect thin film processes developed by us and other suppliers, as well as various measuring instruments, to the line. This way we are positioning ourselves as a systems integrator.