In collaboration with UKAEA, we developed a method that avoids such hurdles. Thereby, the cables are approximated as lines with line elements to describe currents, voltages and temperatures (I, V, T). In the surrounding domain, the magnetic vector potential A is solved for. The method is based on FEM and implemented in COMSOL Multiphysics. Because the method is basically a modification of AV formulation, using an additional variable I for the current in a cable we coin this AVI formulation.

We will first show a benchmark where we compare AVI formulation to a detailed model with the full cable cross section modelled using HФ formulation. We do this for the case of quench propagation along a straight piece of cable. Then we will show an application of the AVI formulation in a simplified toy model.

normal zone propagation benchmark.

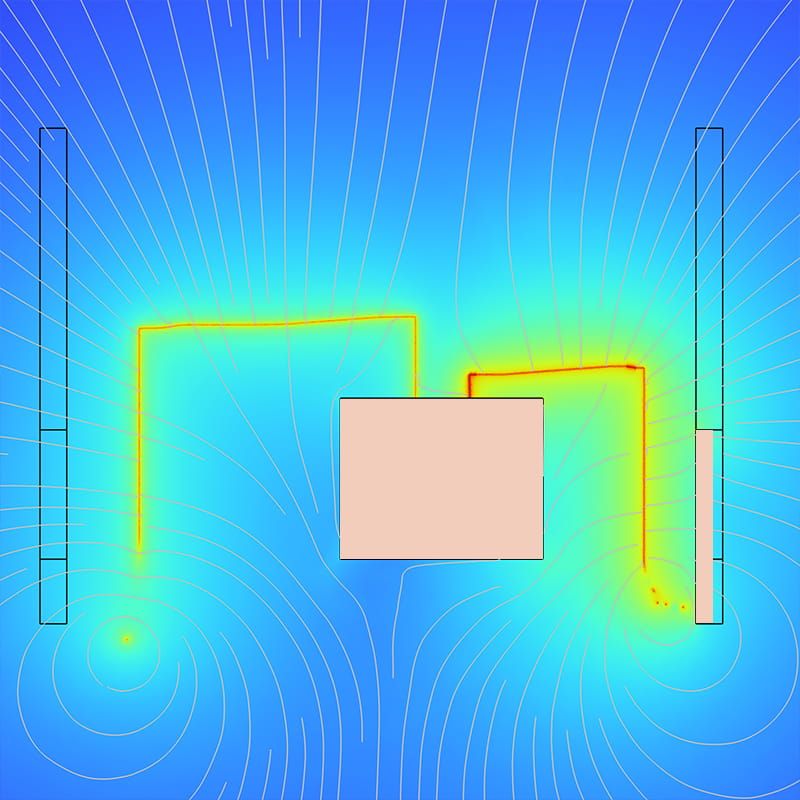

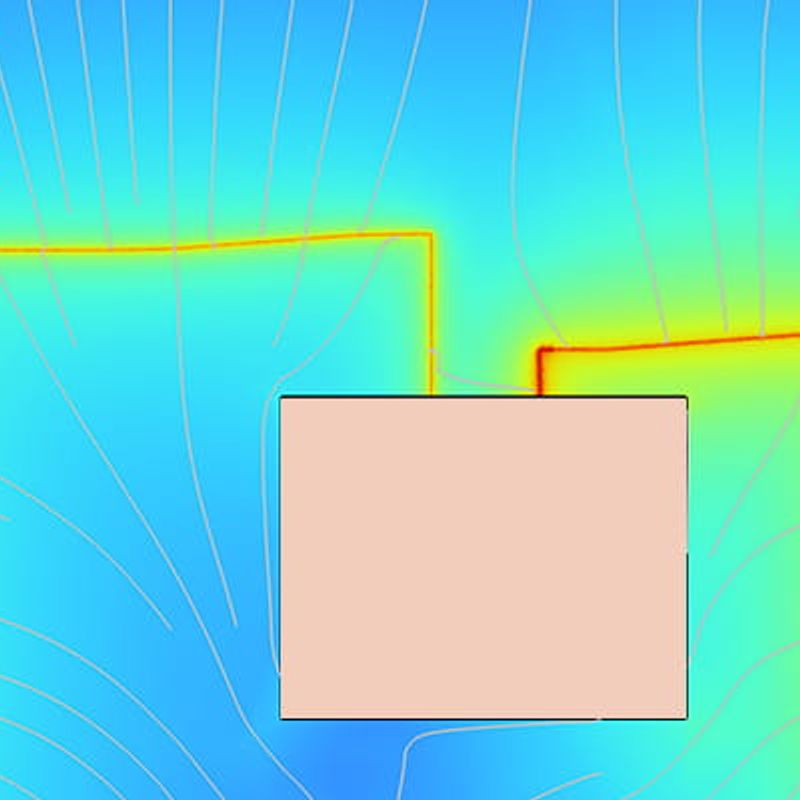

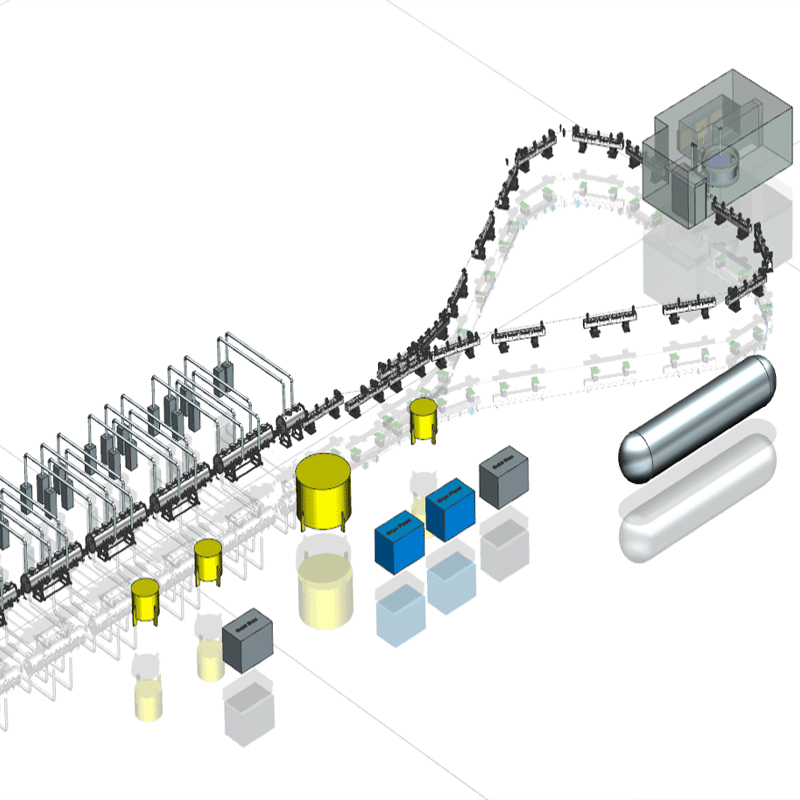

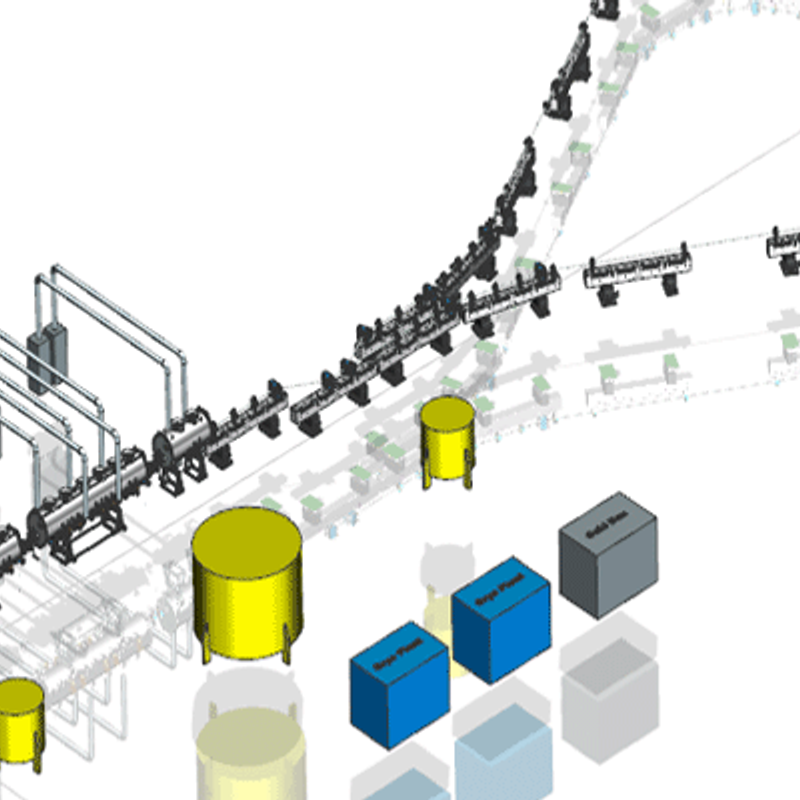

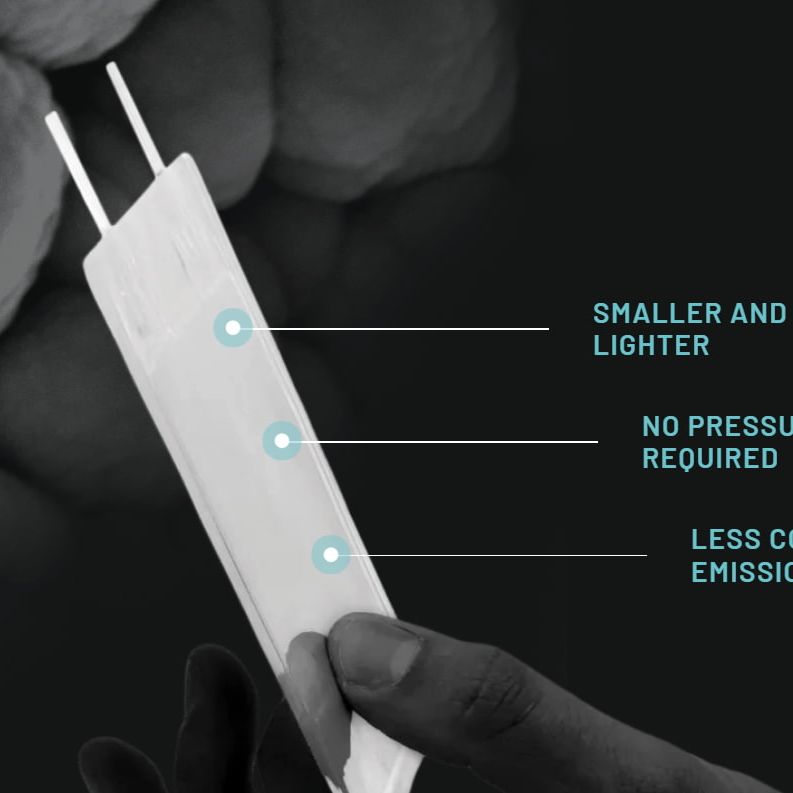

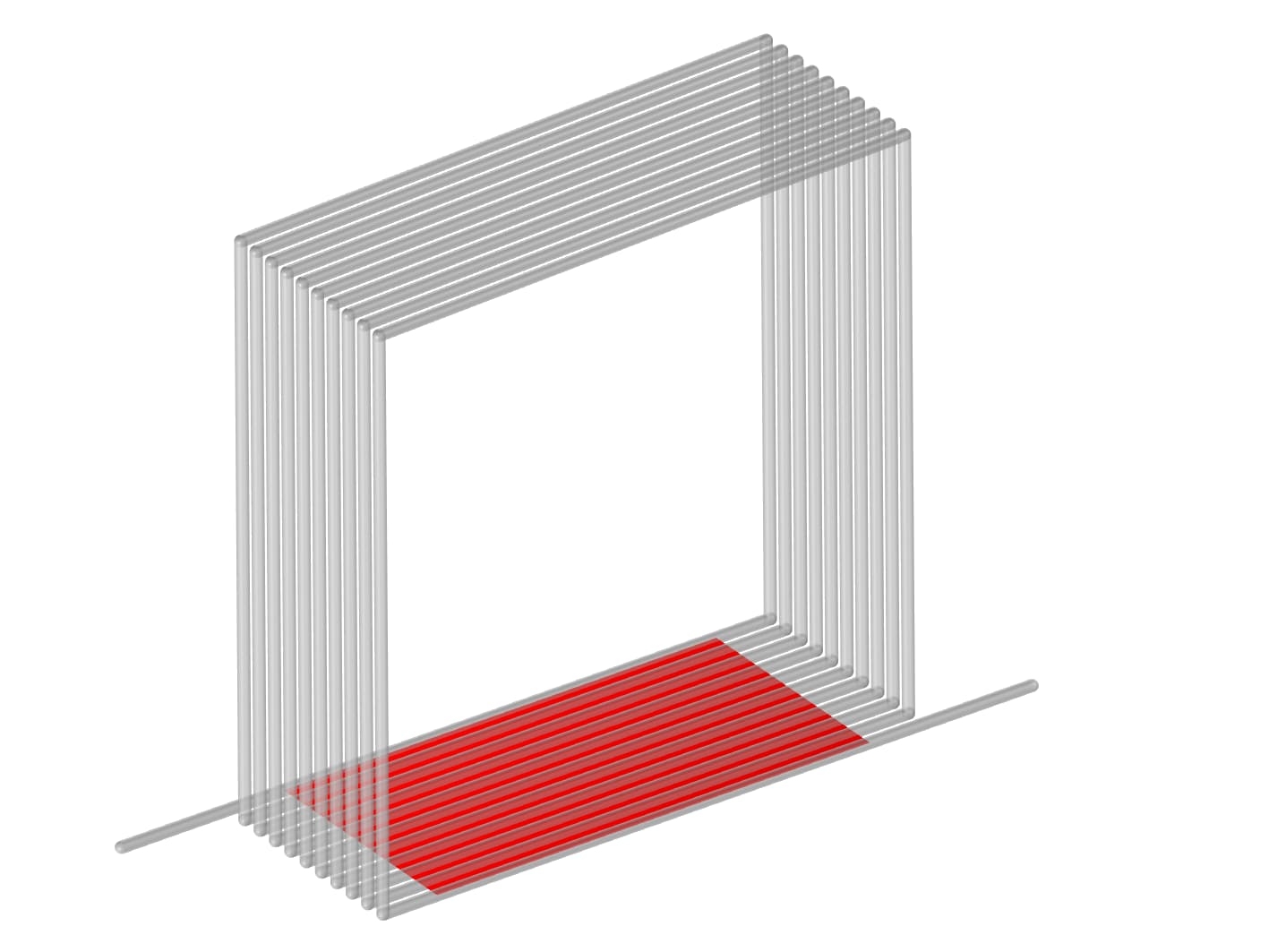

The cable design shown in figure 1 is based on a preliminary design from STEP. The tape stack contains about 200 tapes and its critical current density is B and T dependent. A background field of 10 T is added, making that the critical temperature equal to 73.8 K which is closer to a practical application of this cable. For the AVI model, the detailed cross section is of course not in the model, but electrical and thermal properties are converted into quantities that are averages over the cross section, for example the current sharing resistance per unit length, the heat capacity per unit length, etc. A quench is initiated by artificially ramping down the critical current density to 0 in a certain region (purple in figure 1).

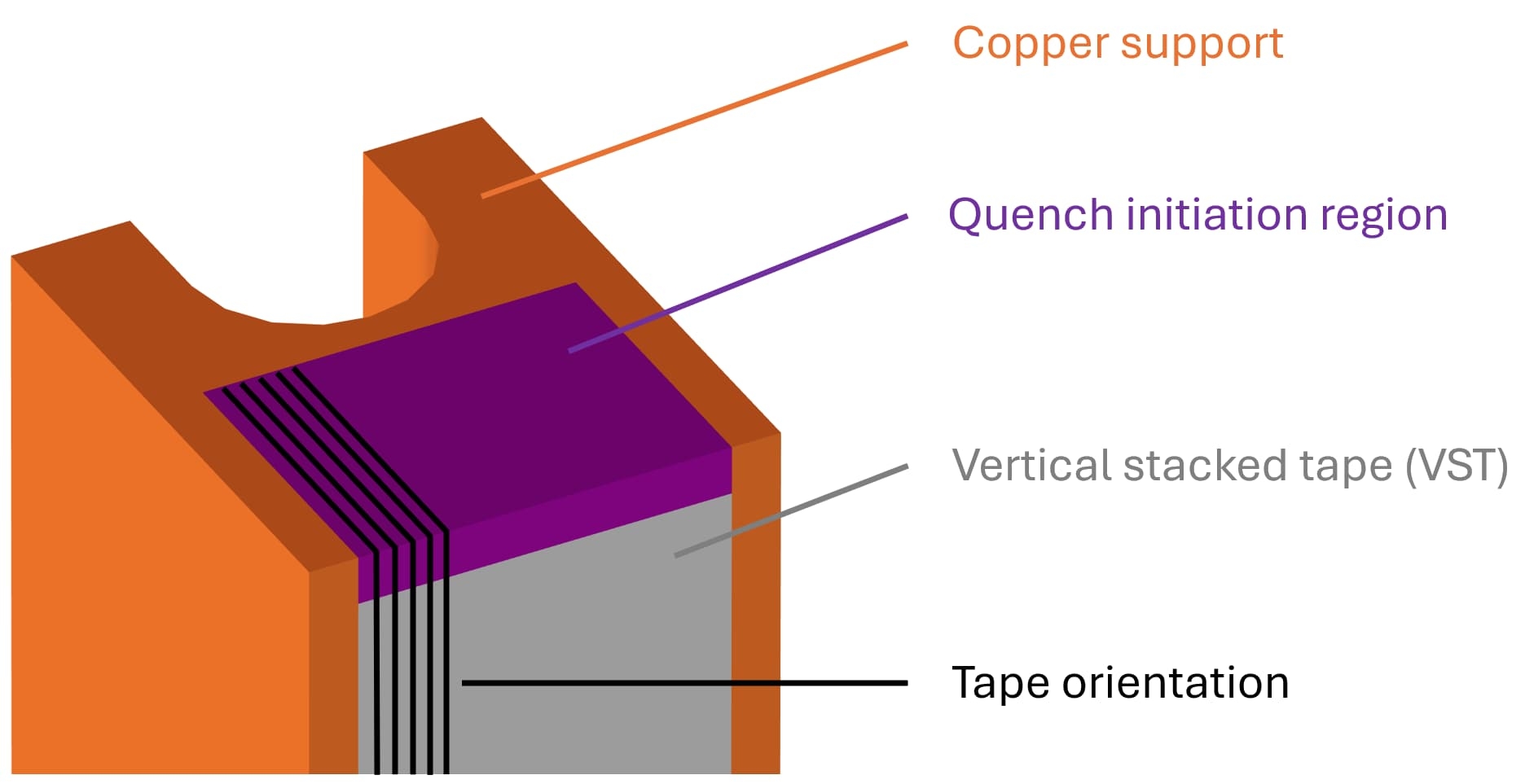

The average temperature in the cable cross section is plotted along the cable length in figure 2 for both methods. The time indications are w.r.t the moment that Tc is reached for the first time. The timing of this moment does not align between the models due to the approximation made in AVI: the 3D nature of the current distribution around the normal zone is ignored, and therefore the heating is slower. However, from this moment onwards the agreement is good enough for all sorts of design purposes. And especially so when considering that the AVI model computes in a few minutes, whereas the HФ model takes a few hours.

toy model: a heater for quench protection.

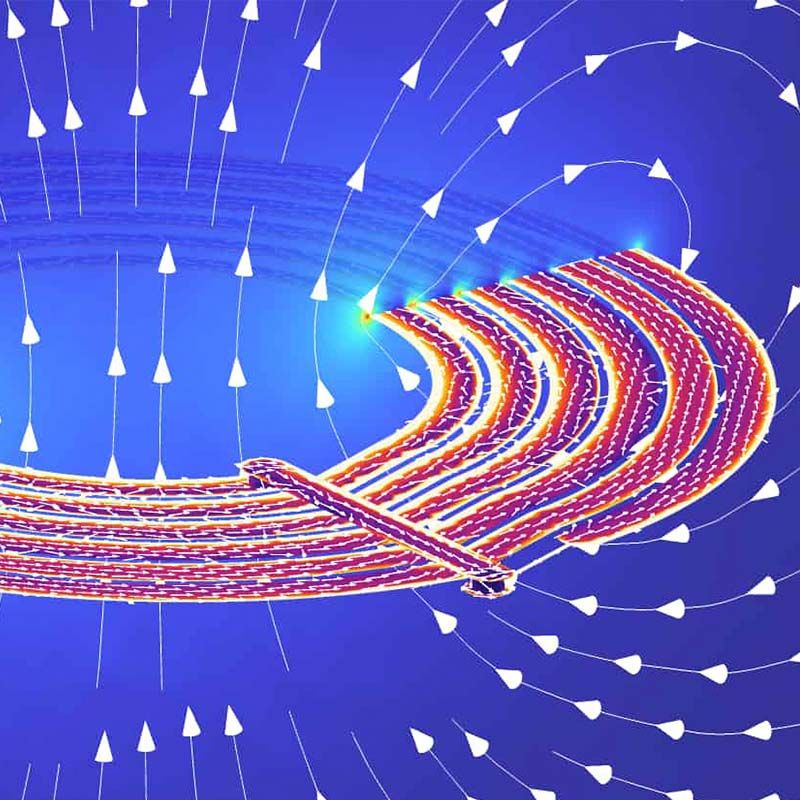

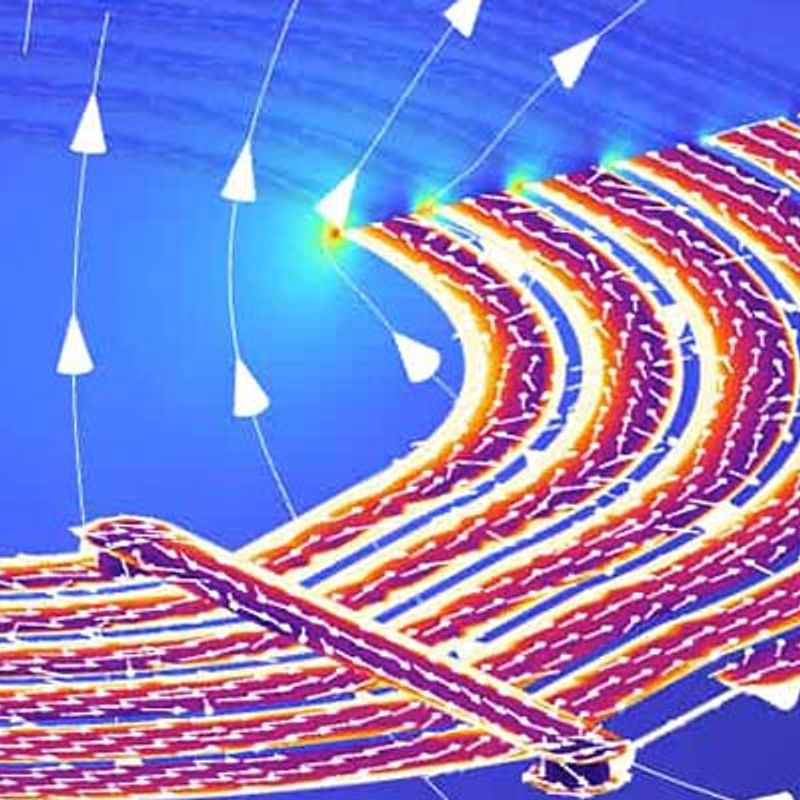

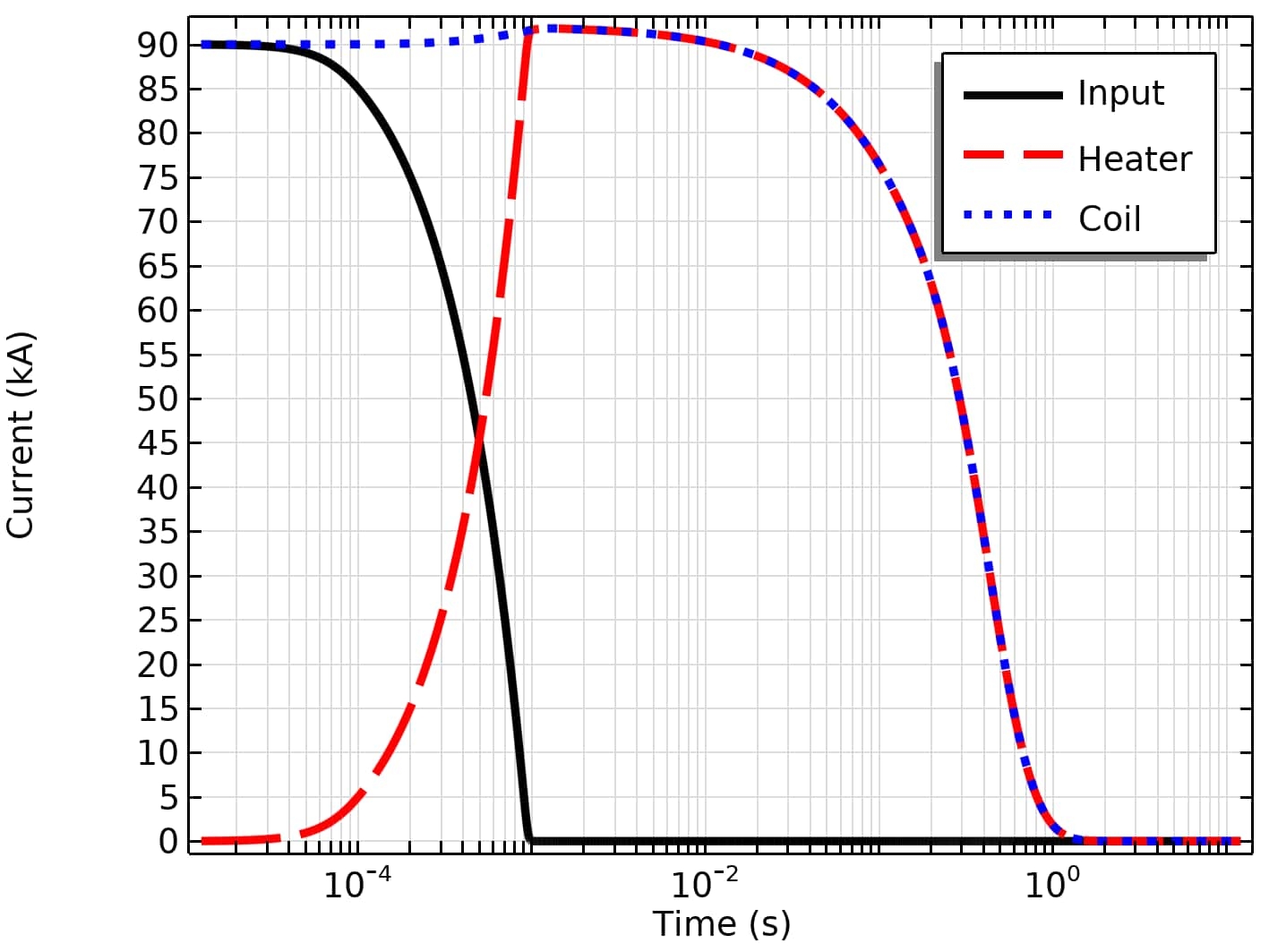

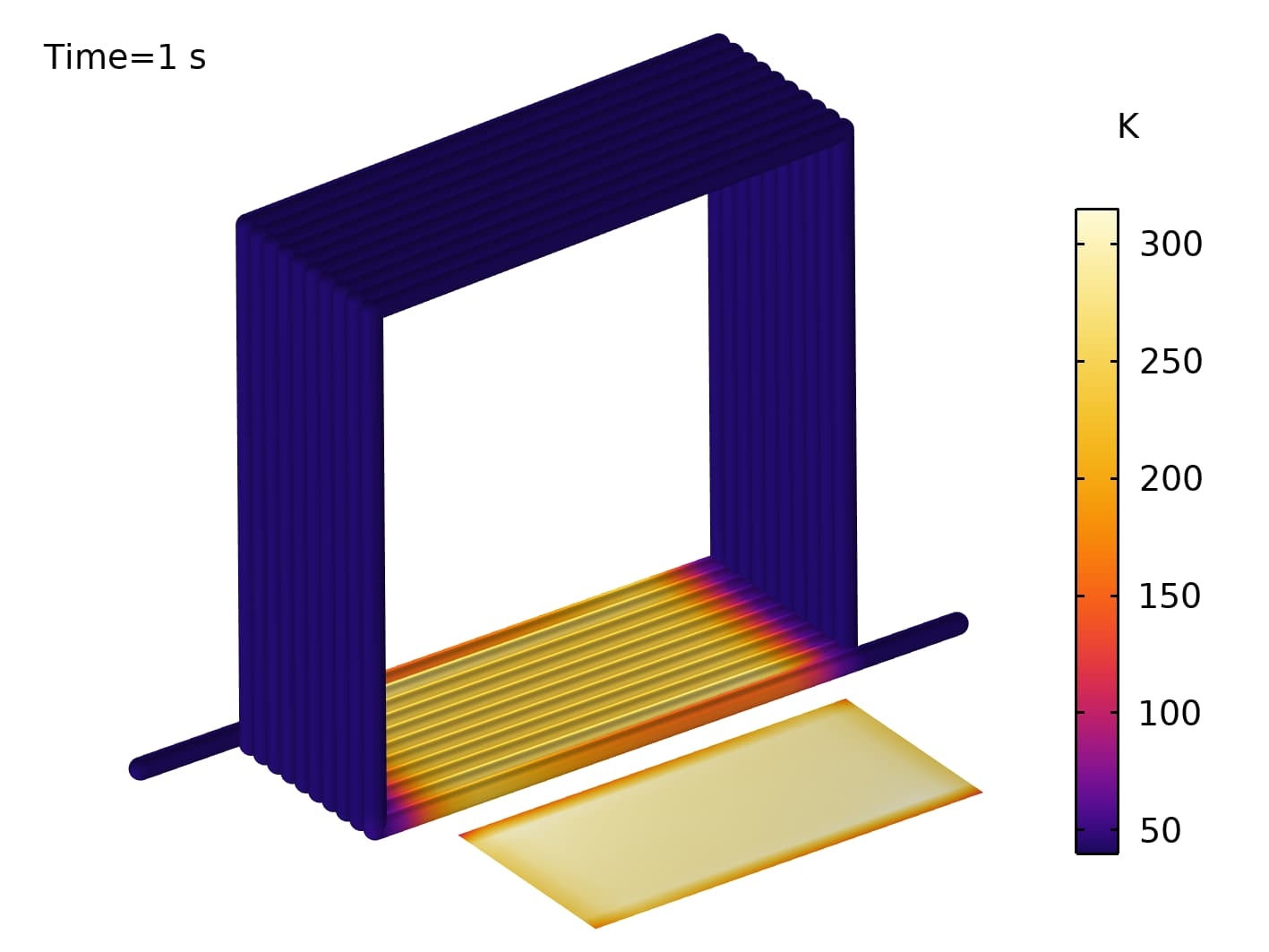

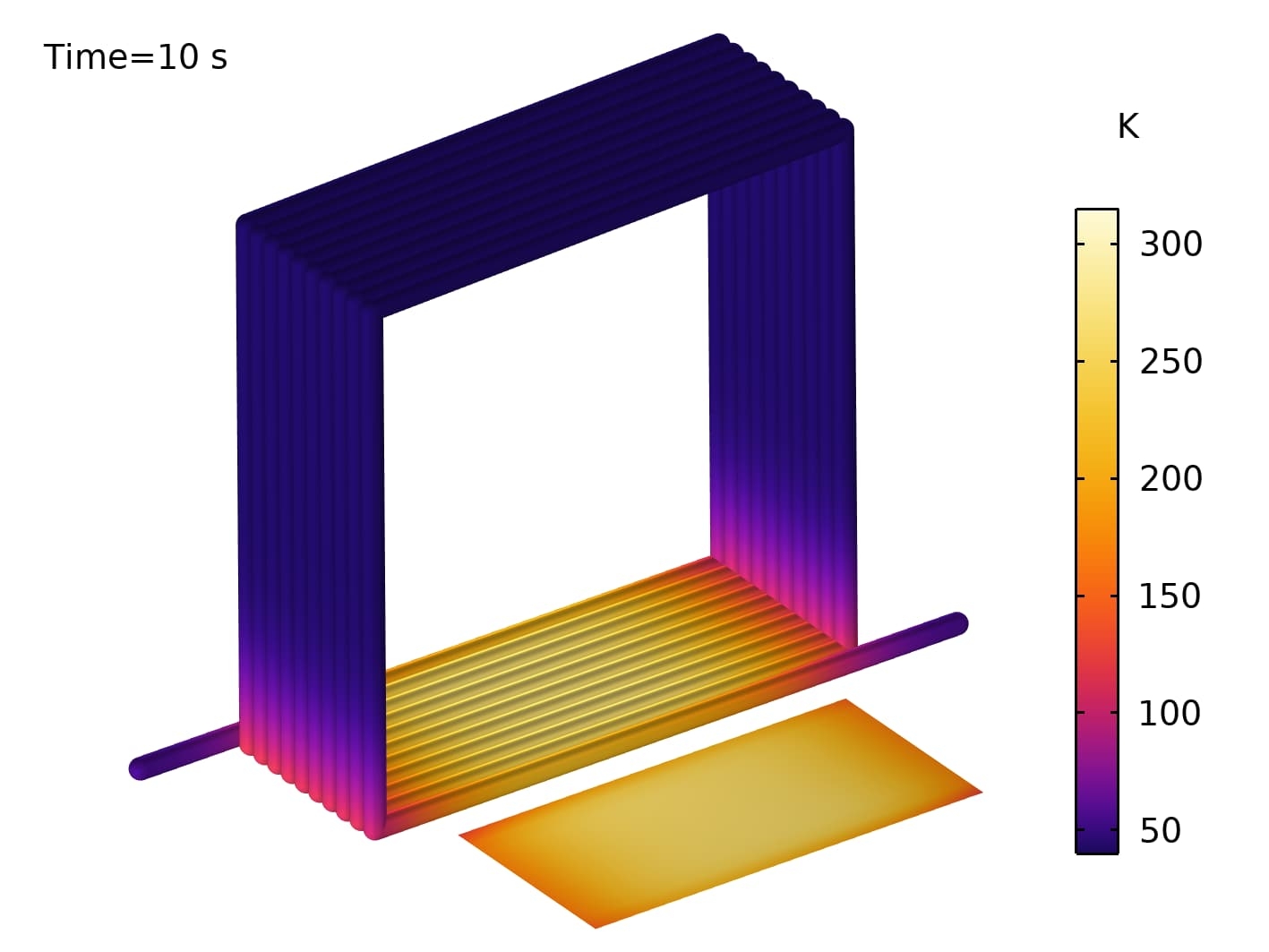

Figure 3 shows a simple 1m x 1m coil that we use to demonstrate the physics of a heater that is used for quench protection purposes. The scenario is a discharge: the current in this coil is ramped down from 90 kA to 0 within 1 ms. Because the inductance of the coil impedes such a fast decay of the flux, that means 90 kA runs through the heater after 1 ms, see figure 4.

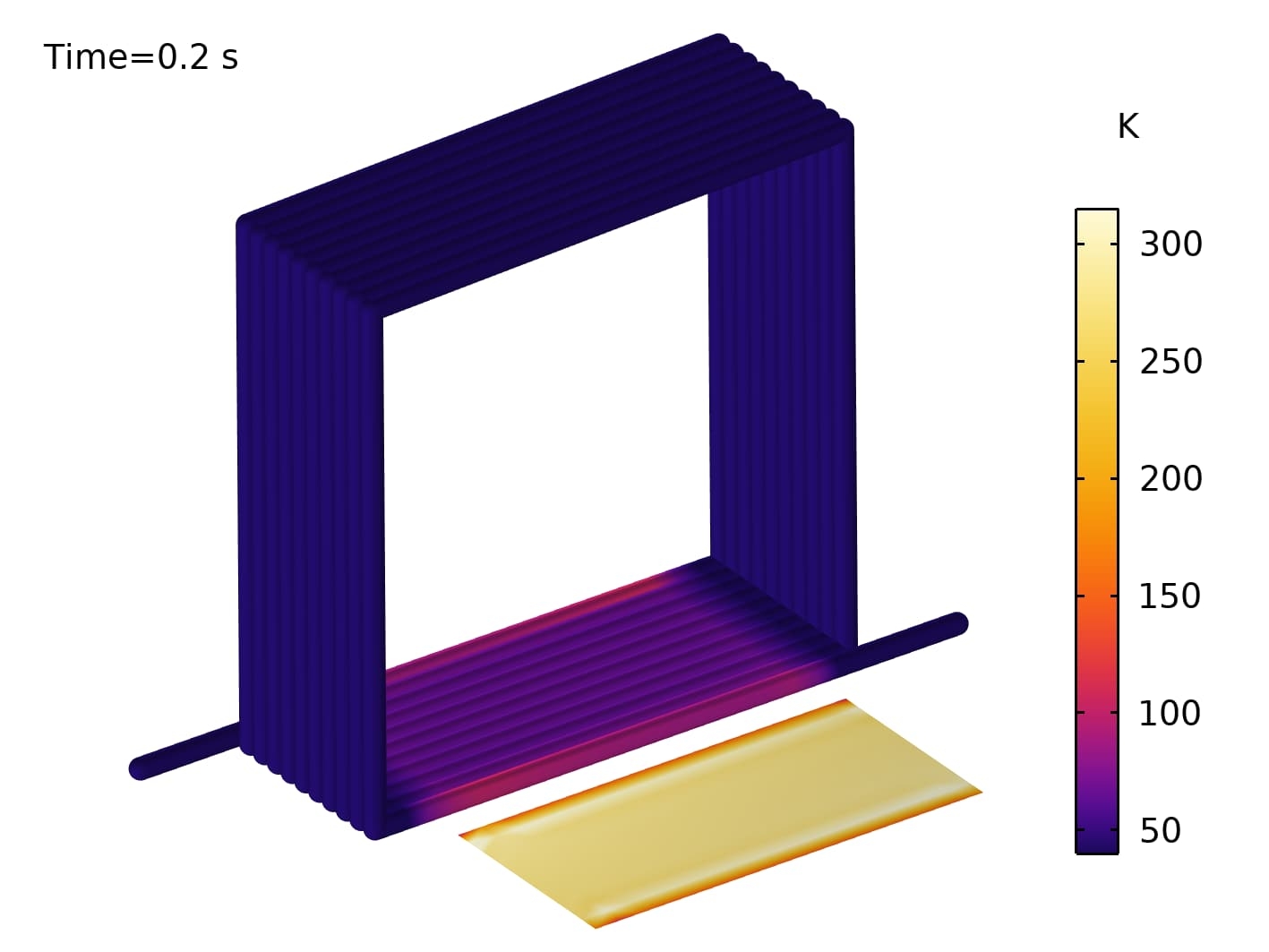

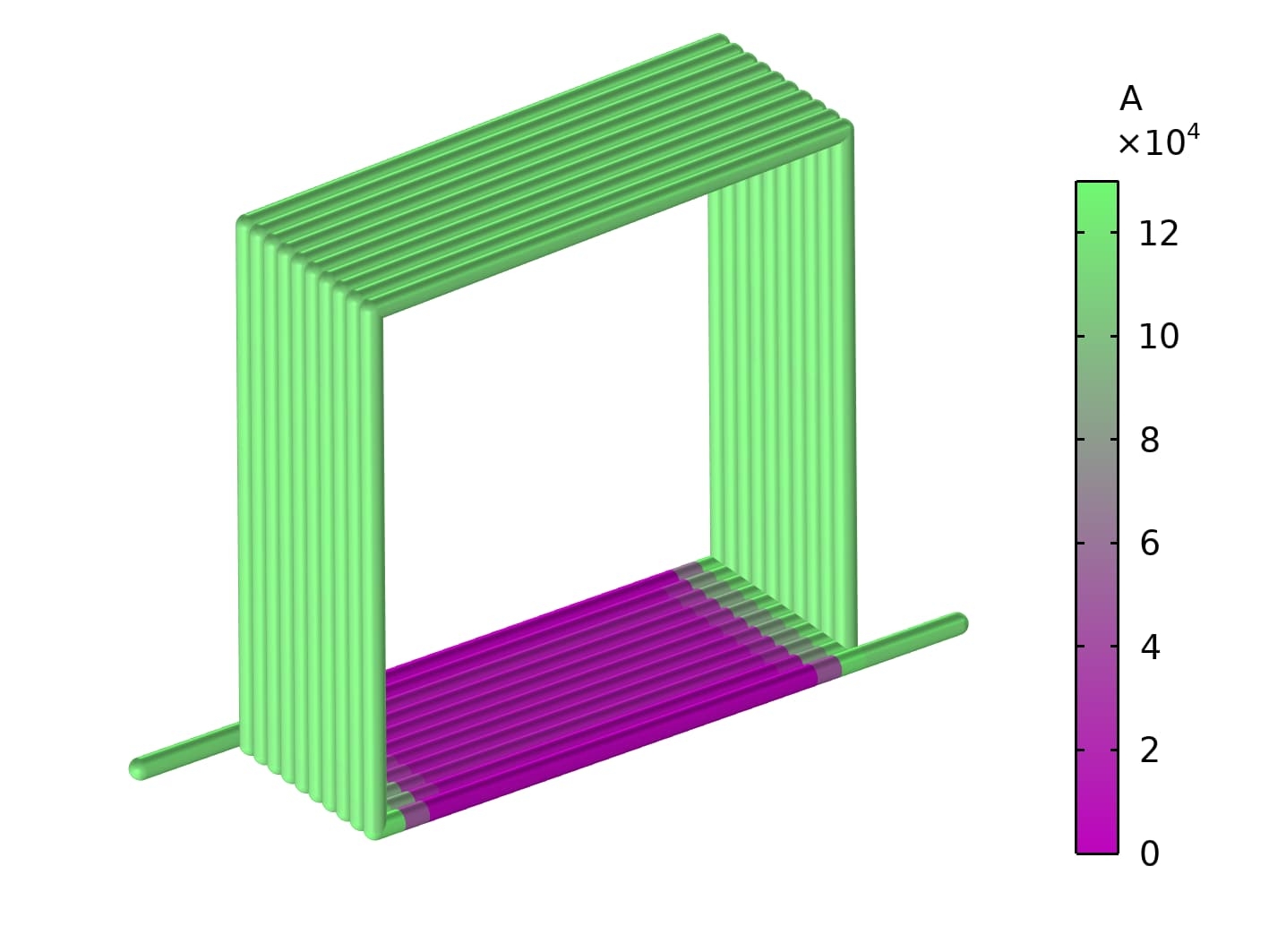

The heater is electrically and thermally connected to the first and last turn, but only thermally to the turns in between. The heater heats up quickly and due to this thermal connection, the temperature in 1 leg of the coil quickly (before all magnetic energy is dissipated) rises above Tc, see figure 5. This makes sure the dissipation is distributed over a sizable part of the coil and not all magnetic energy is dumped in a single hotspot. After roughly 1 s (related to the characteristic L / R time of the system) the current has damped out and temperature peaks will only decrease due to thermal diffusion. In figure 6 we can observe the maximum temperature in the cables stays below room temperature.

The example shown here is very simple, but the method can be applied to much more complicated geometries, connecting the line elements to any 2D or 3D structures or external circuits. This way fast iterations are possible, from which many valuable insights can be obtained. UKAEA uses this method for the design of the quench protection system of the toroidal field coils. This work has been funded by STEP, a major technology and infrastructure programme led by UK Industrial Fusion Solutions Ltd, which aims to deliver the UK’s prototype fusion powerplant and a path to the commercial viability of fusion.

"it is a risky business"

“It is a risky business to develop a custom formulation and its implementation: one does not know in advance how well it is going to work. This aspect draws the character of the work a bit from science towards art (just a little bit). Experience informed guesses as to what features will work well, reduce the amount of trial and error, but a certain amount still remains. This can cause some stress, but that makes it all the more satisfactory if the method turns out to work smoothly in the end.”

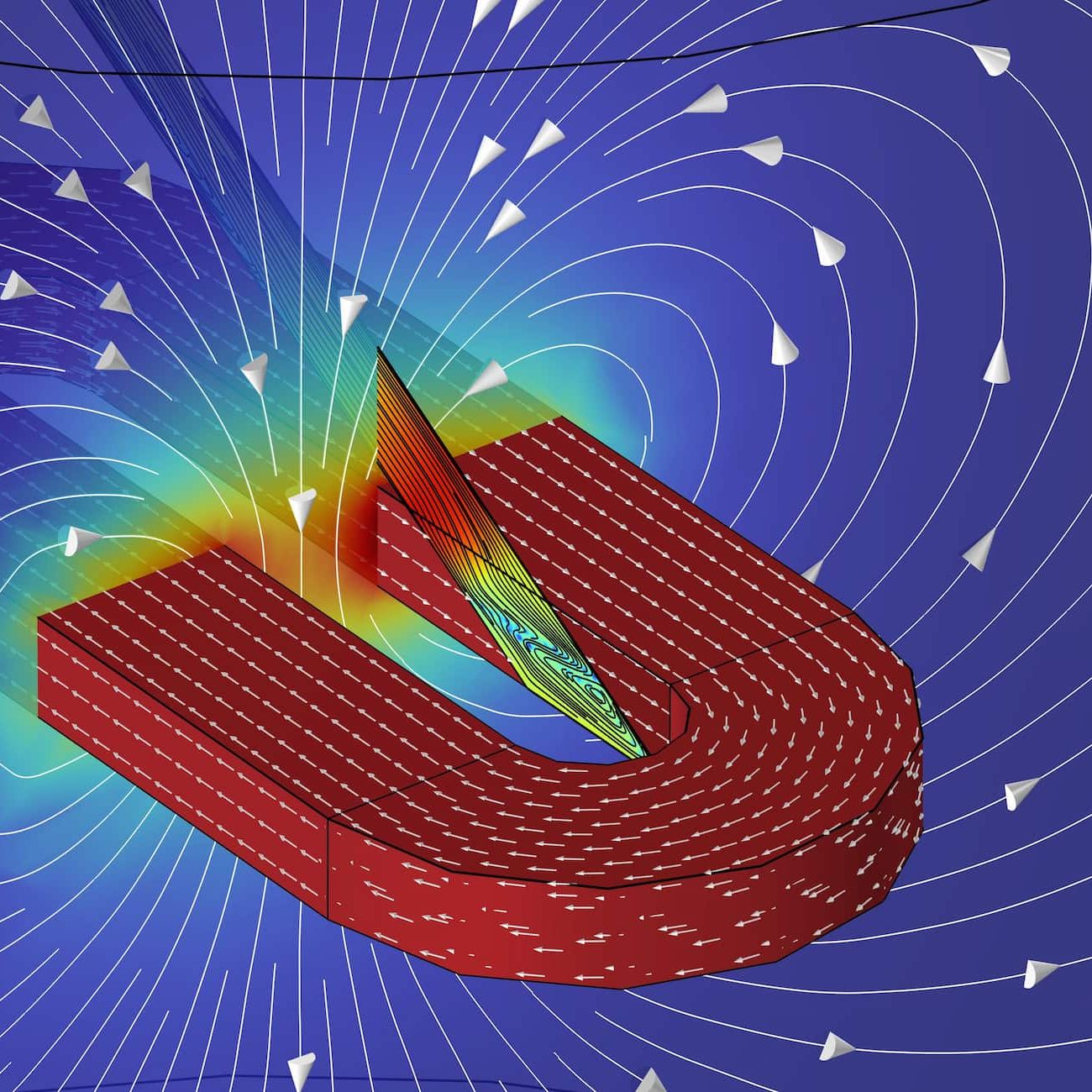

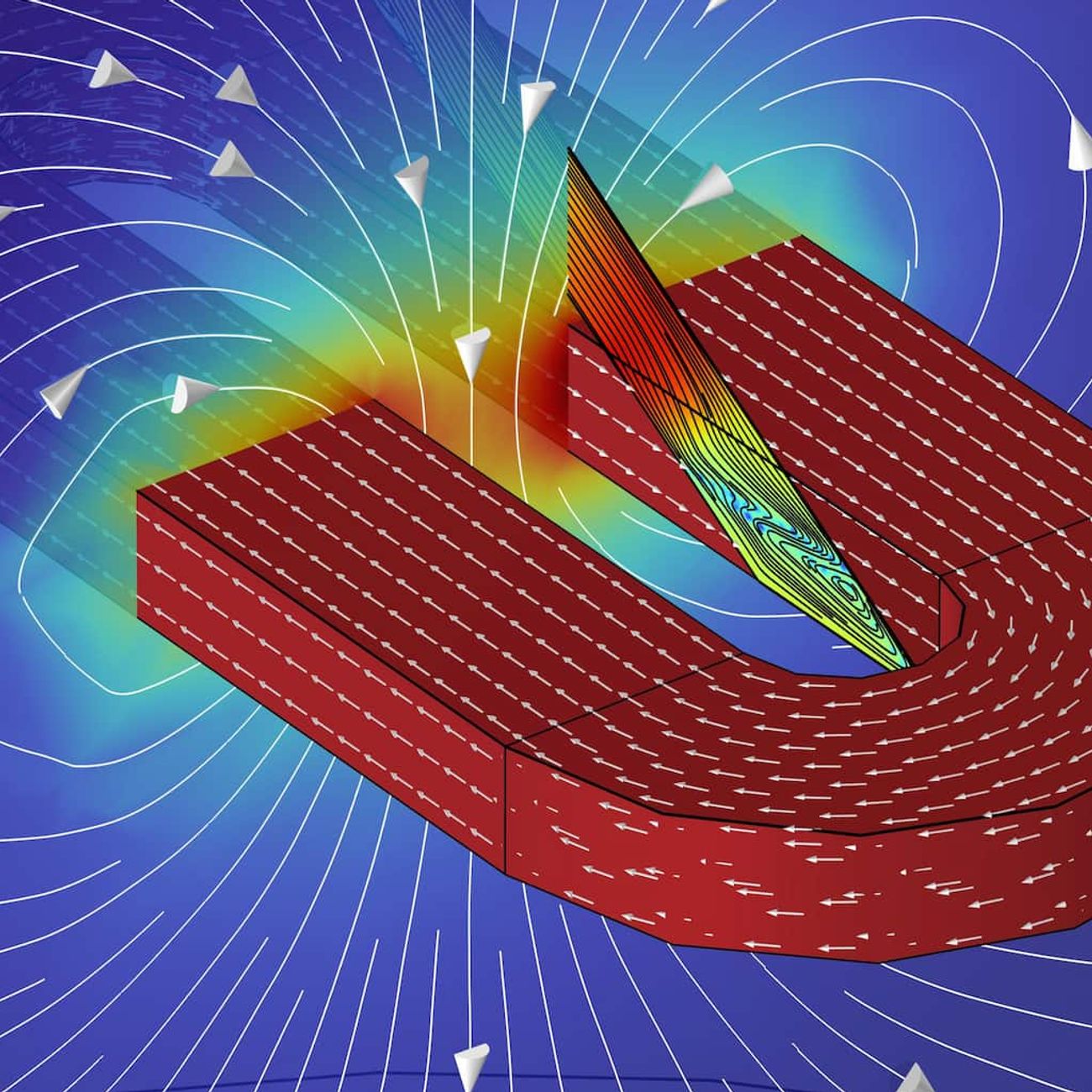

more electromagnetism.

Demcon multiphysics.

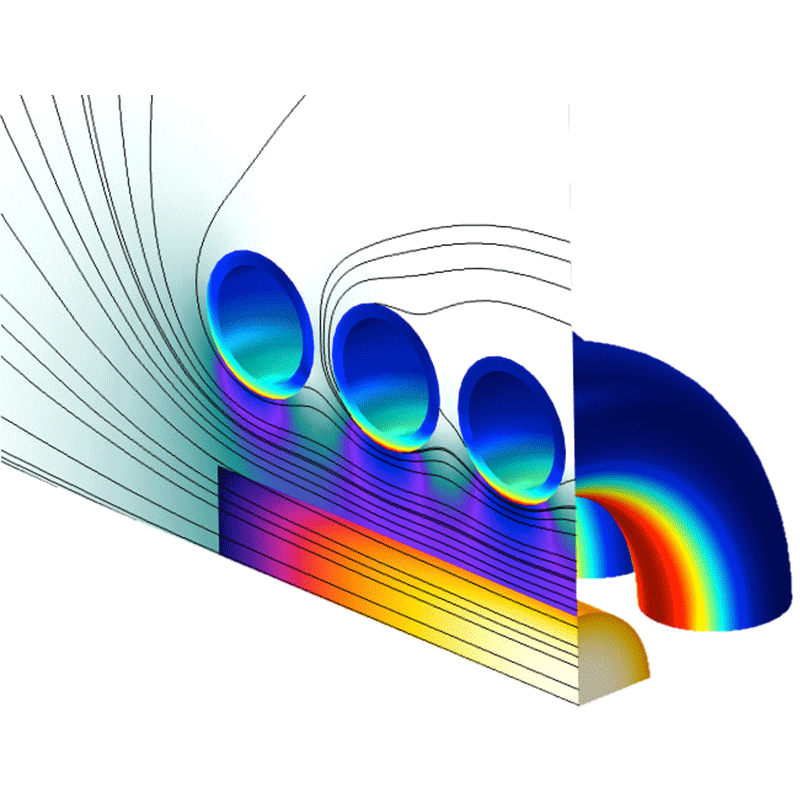

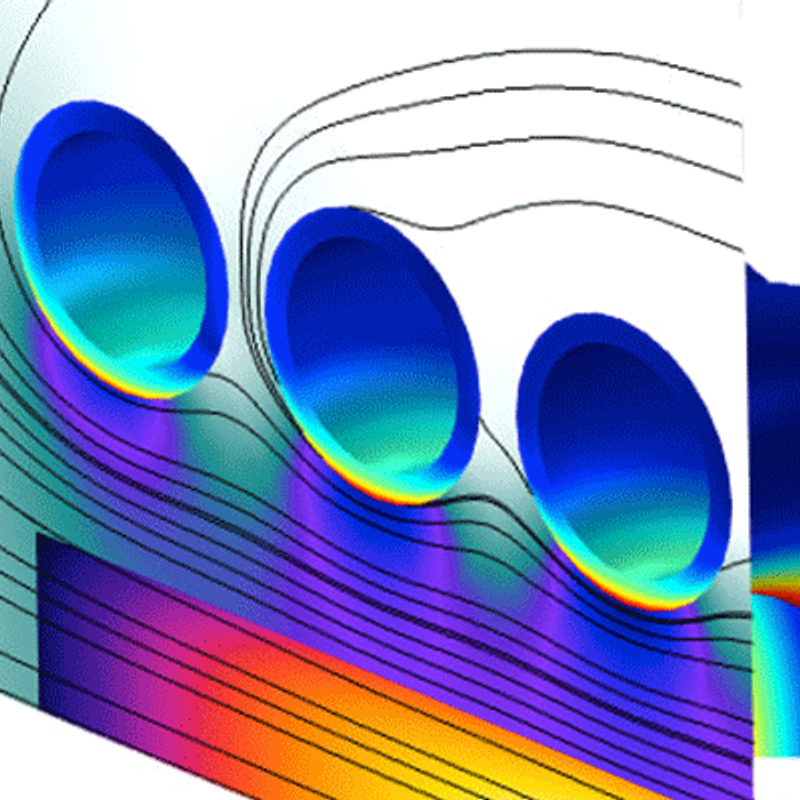

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.