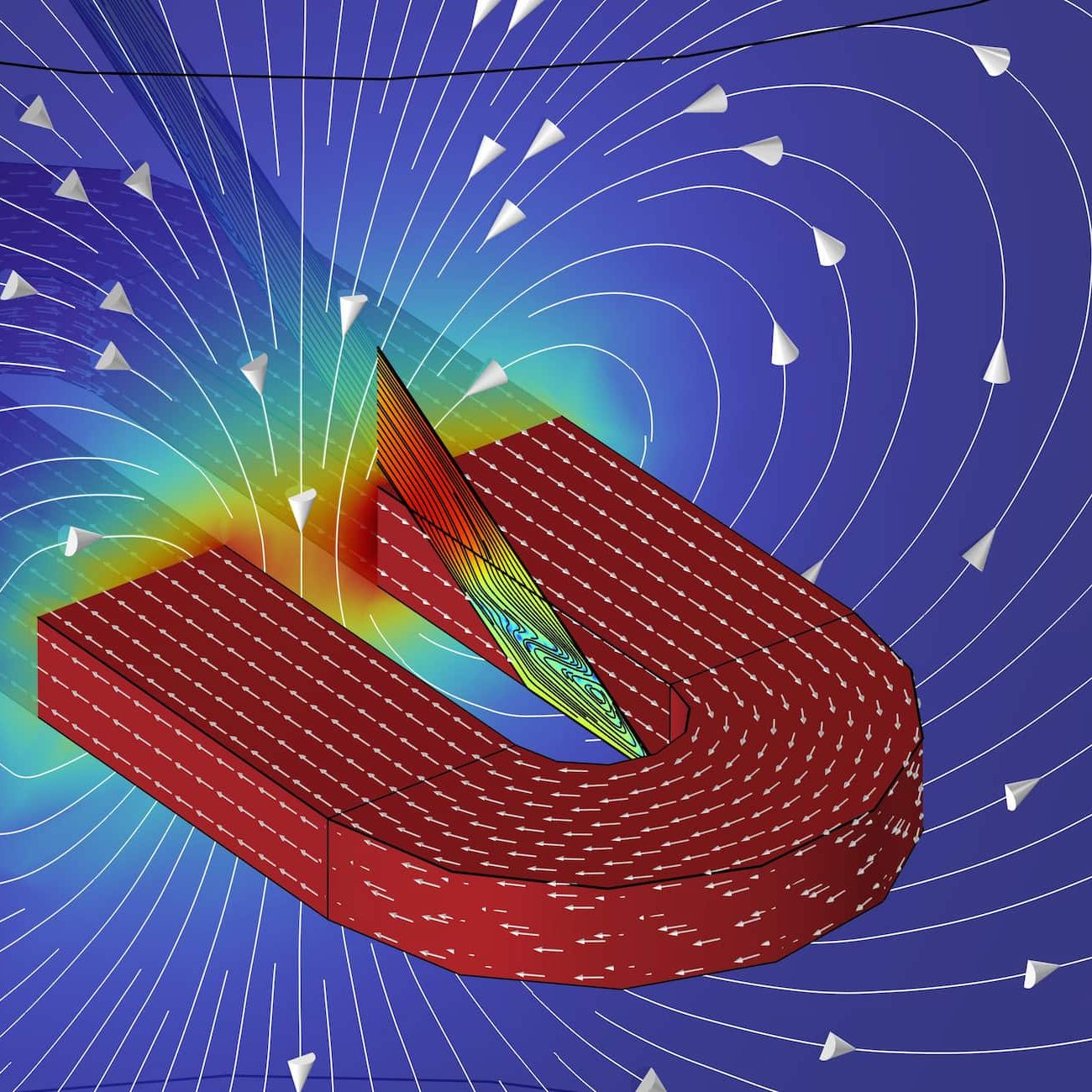

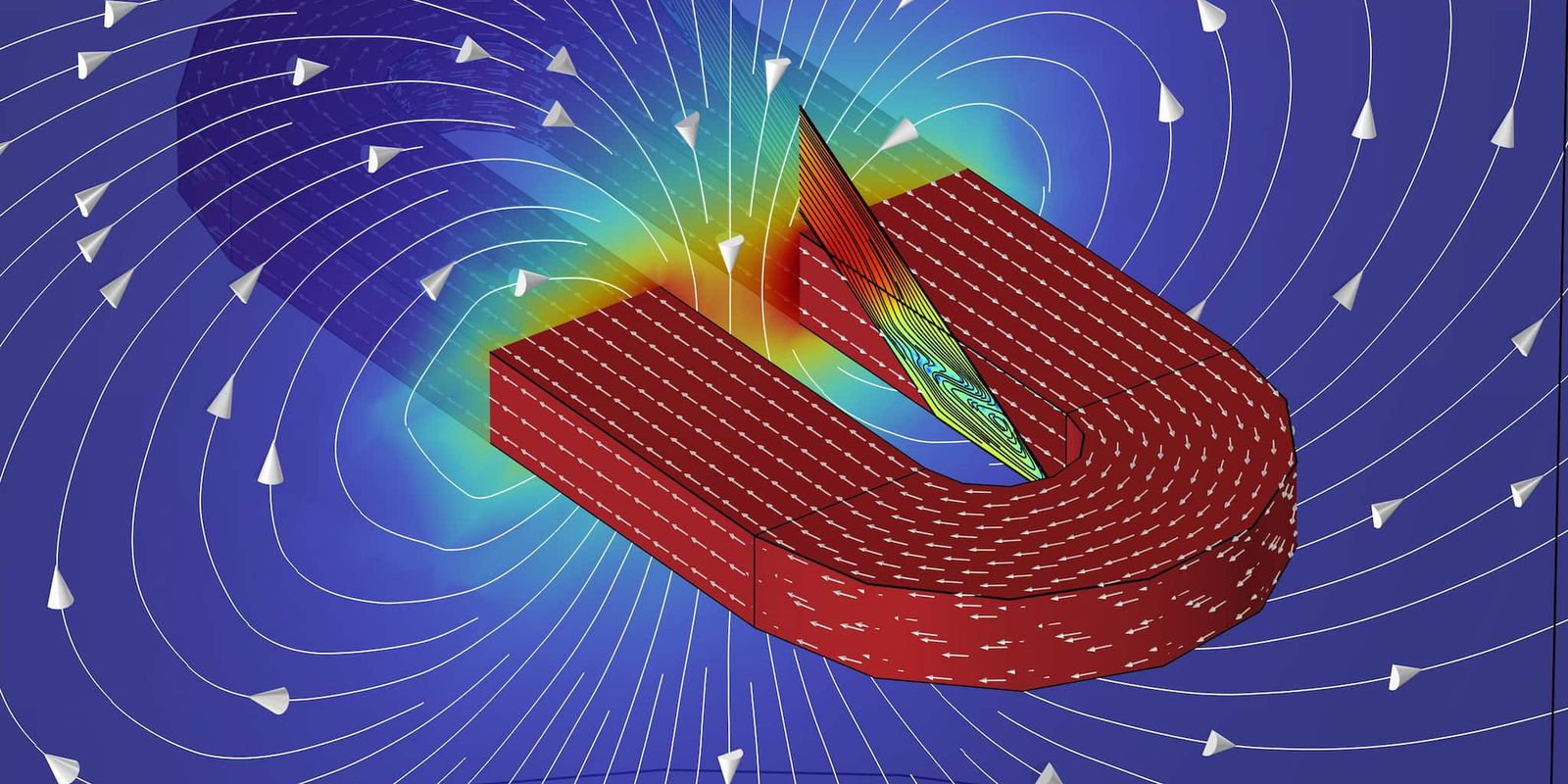

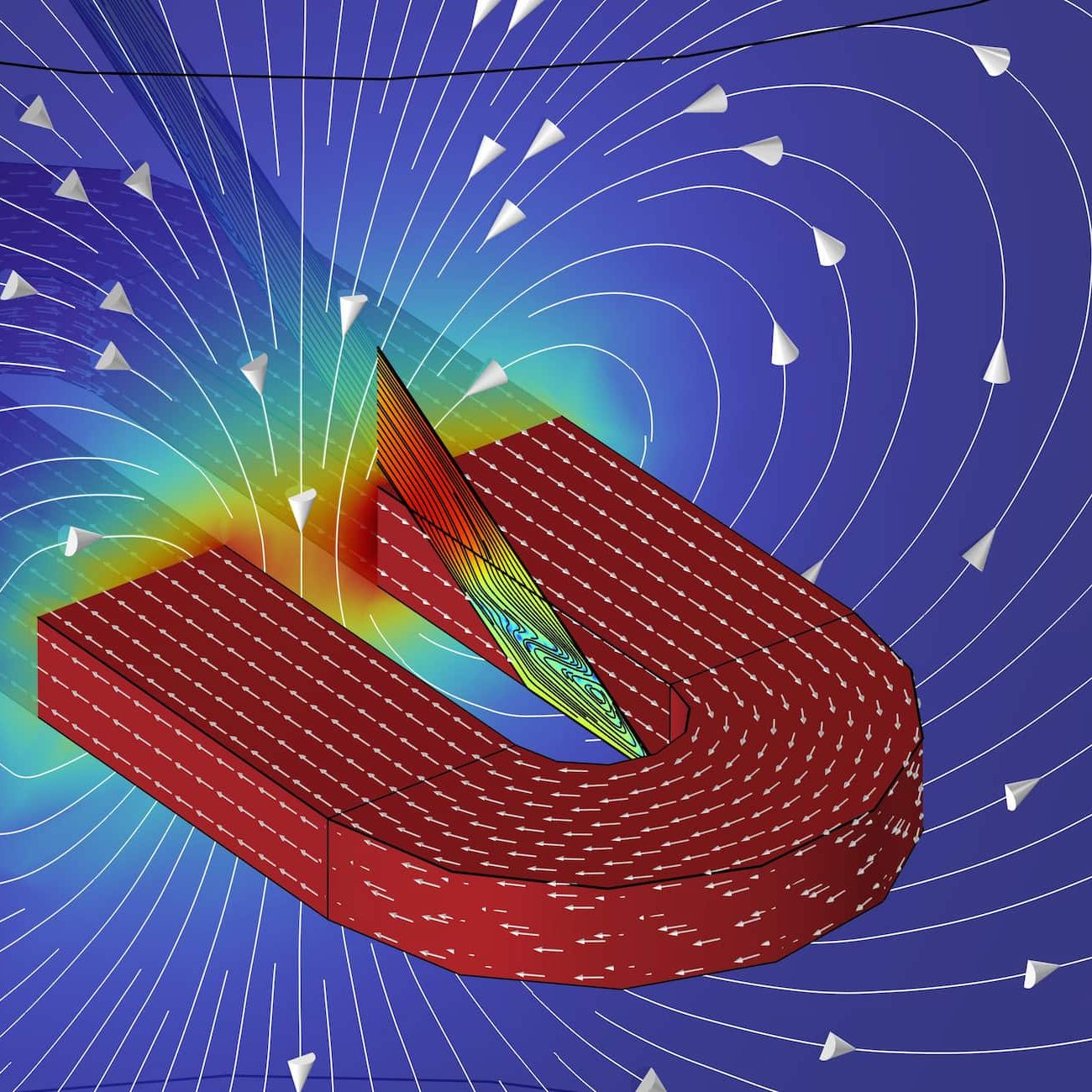

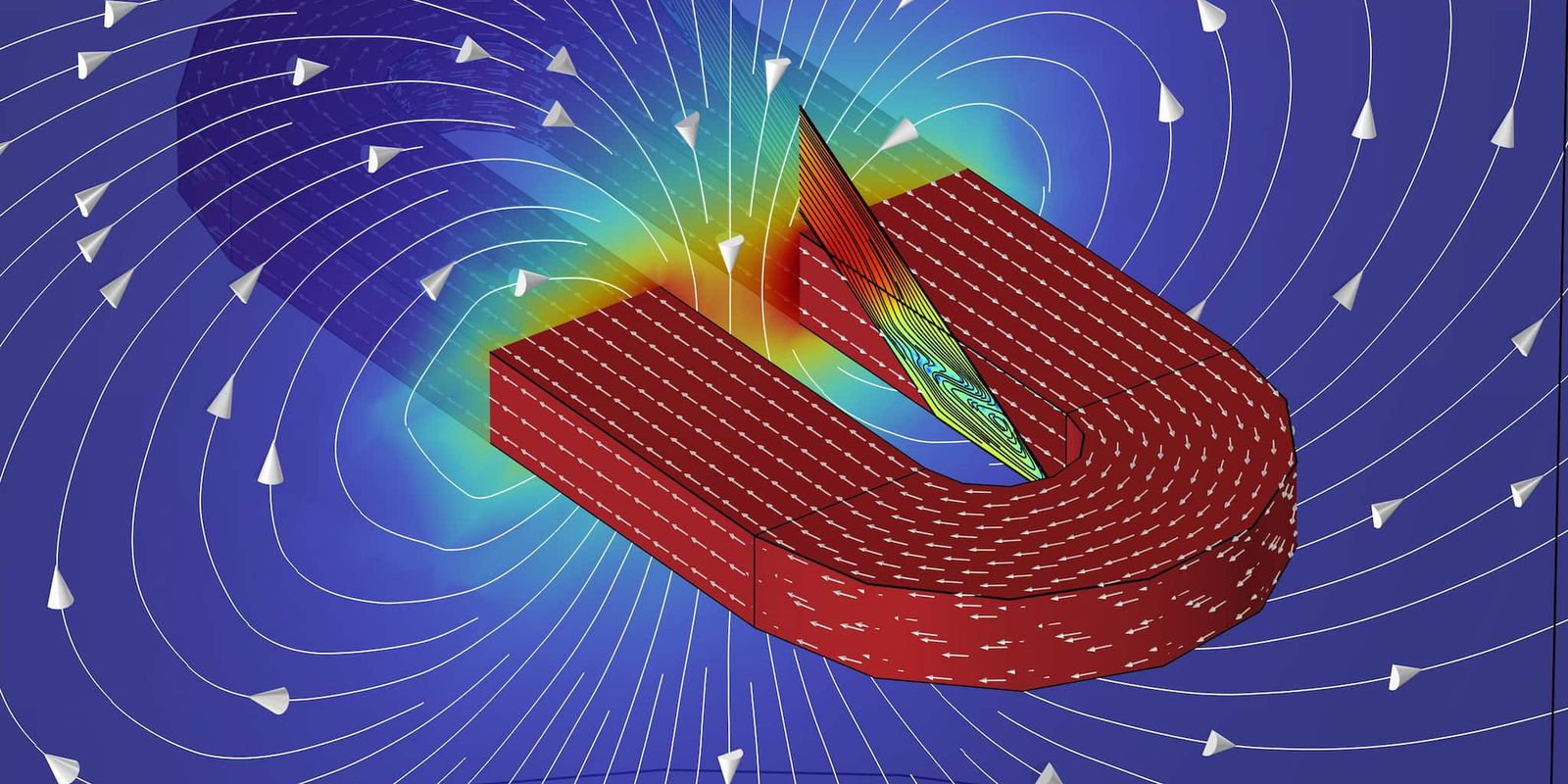

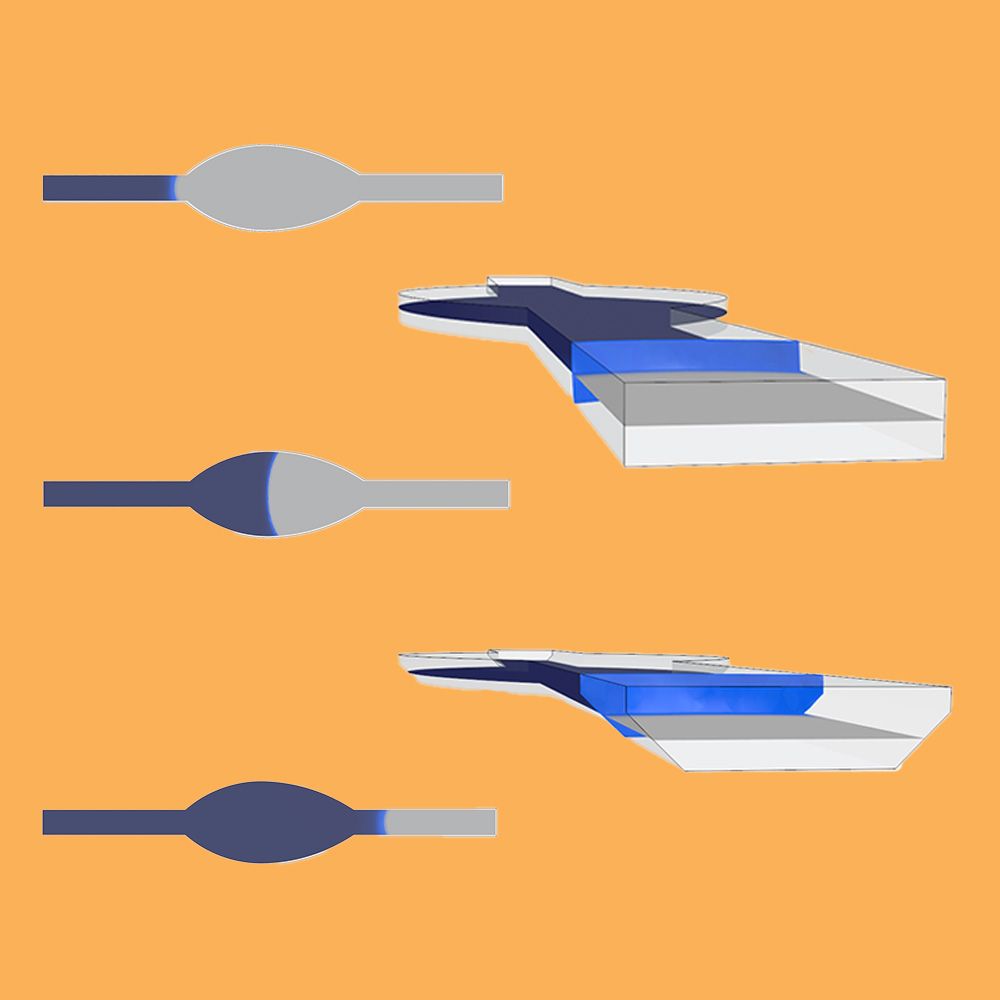

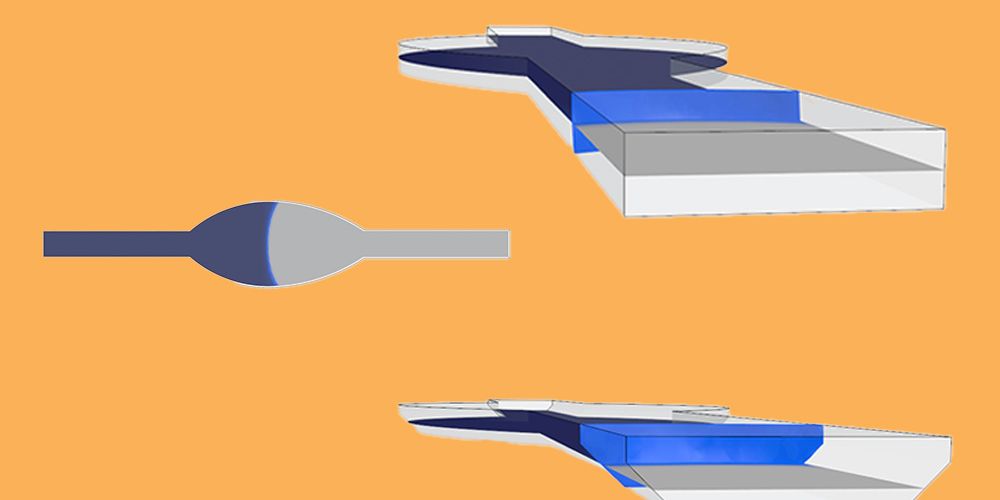

predicting the critical current in the lead cable of a superconducting coil.

using a custom modified AV formulation we extracted the critical current of a superconducting lead in a superconducting coil

Read more

Our passion is to combine multiphysics expertise and simulation skills for solving complex issues of a technological and social nature. We want to create a direct or indirect impact on people and their living environment. To this end, we contribute to the design of advanced systems and innovative products for our customers. As far as confidentiality permits, we proudly share our results. Each showcase presents a unique problem we tackled. Our showcases demonstrate the broad multiphysics expertise we can invoke, the ingenious simulation solutions we devise and the added value we provide to our customers.

using a custom modified AV formulation we extracted the critical current of a superconducting lead in a superconducting coil

Read more

.jpg)

.jpg)

.jpg)

.jpg)

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, COMSOL, STAR-CCM+, Simcenter, Mathworks and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.