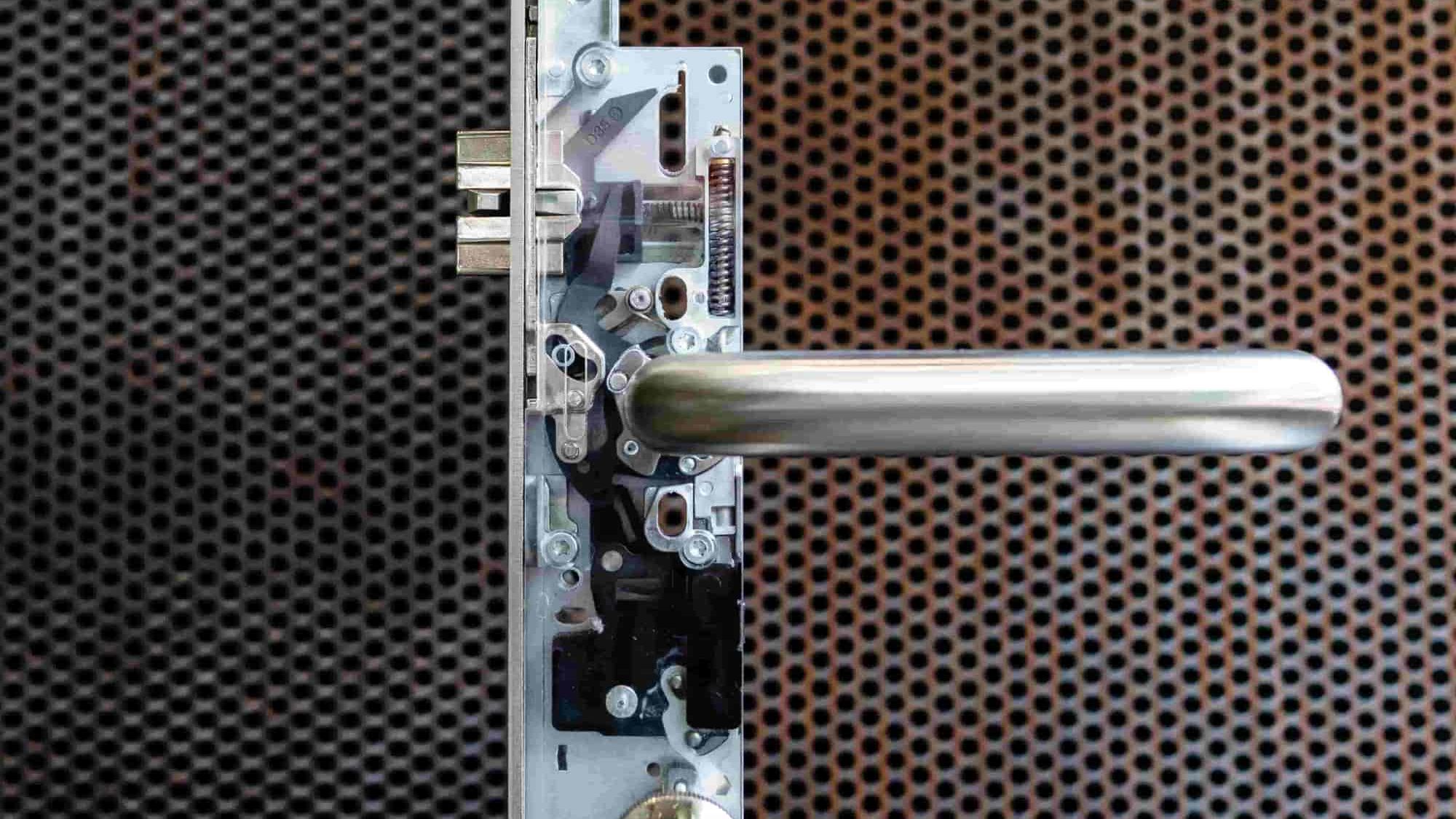

When a door is forced open, it should withstand forces in

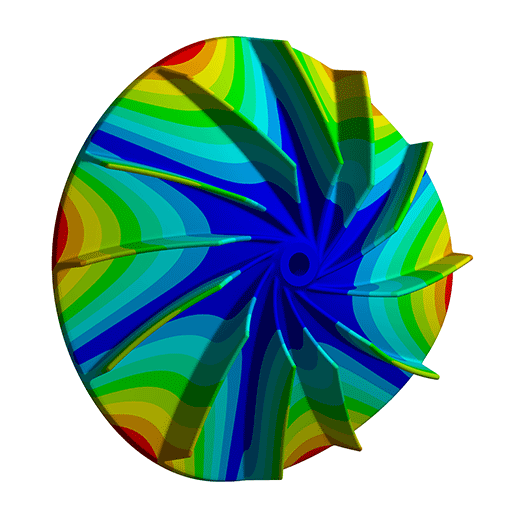

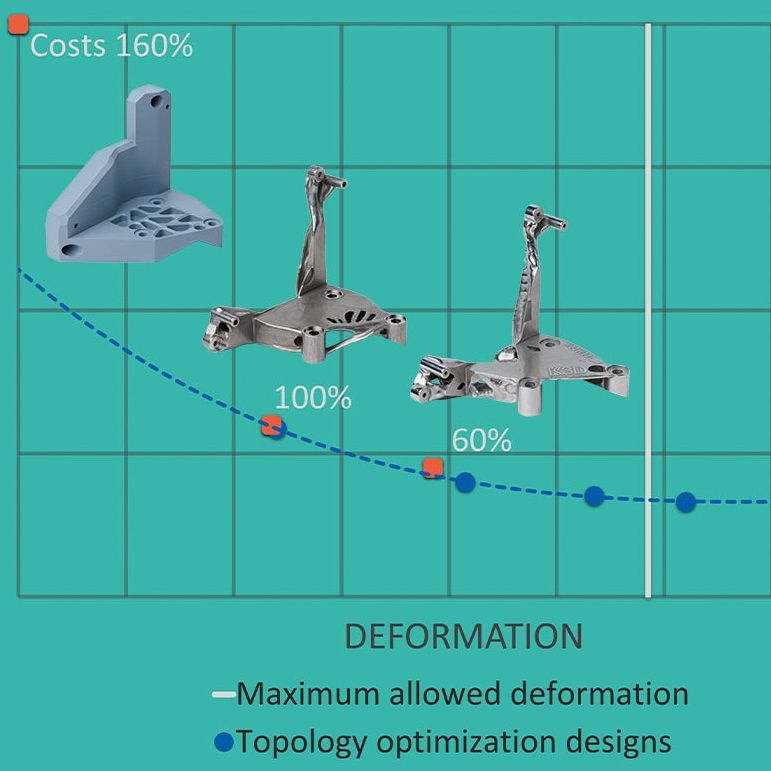

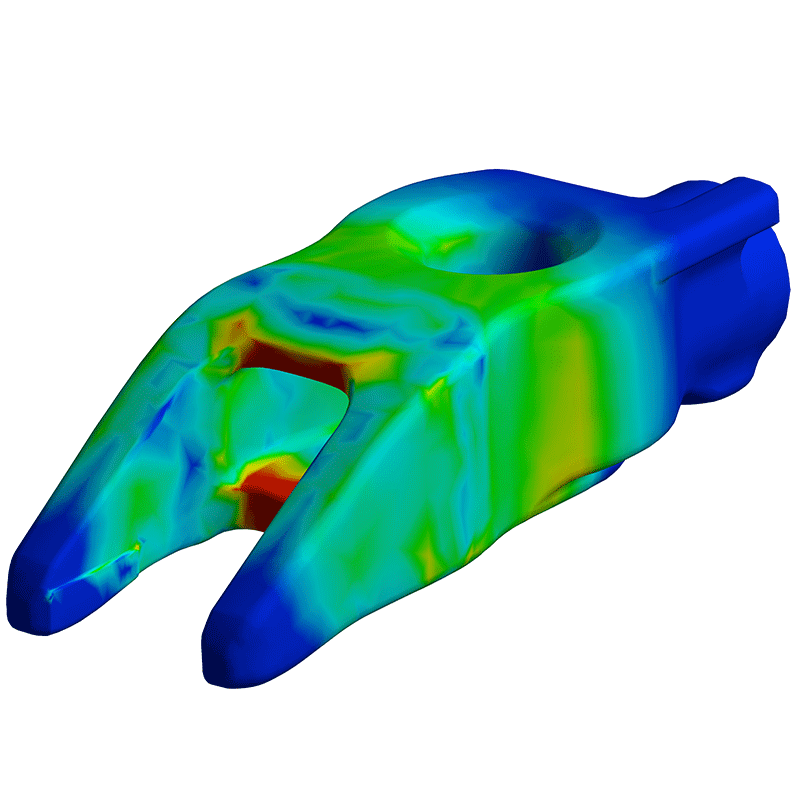

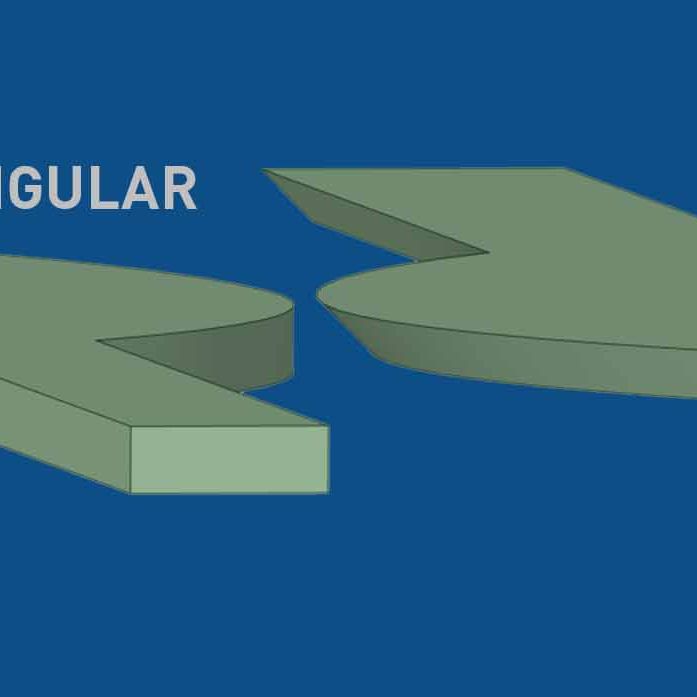

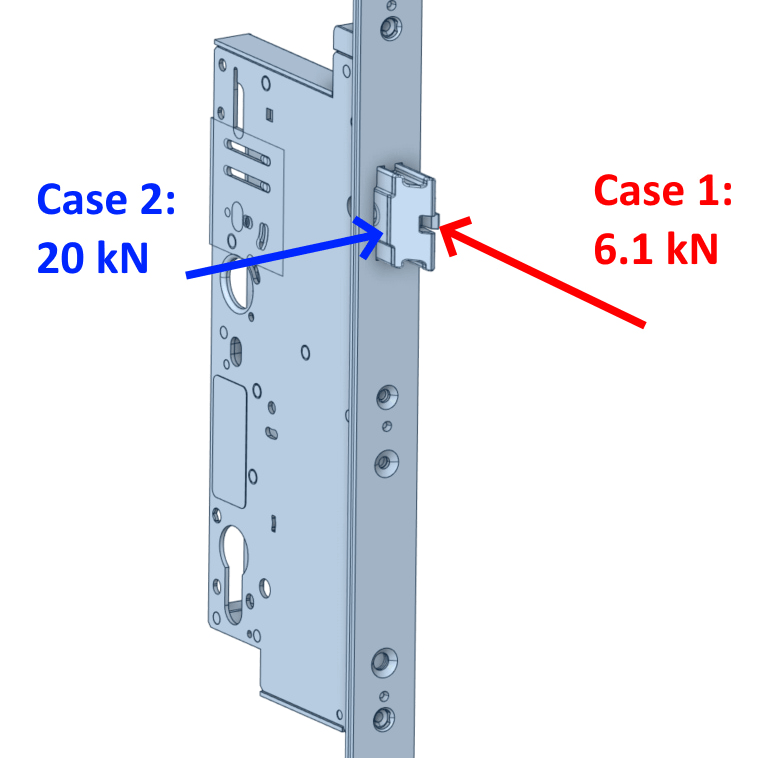

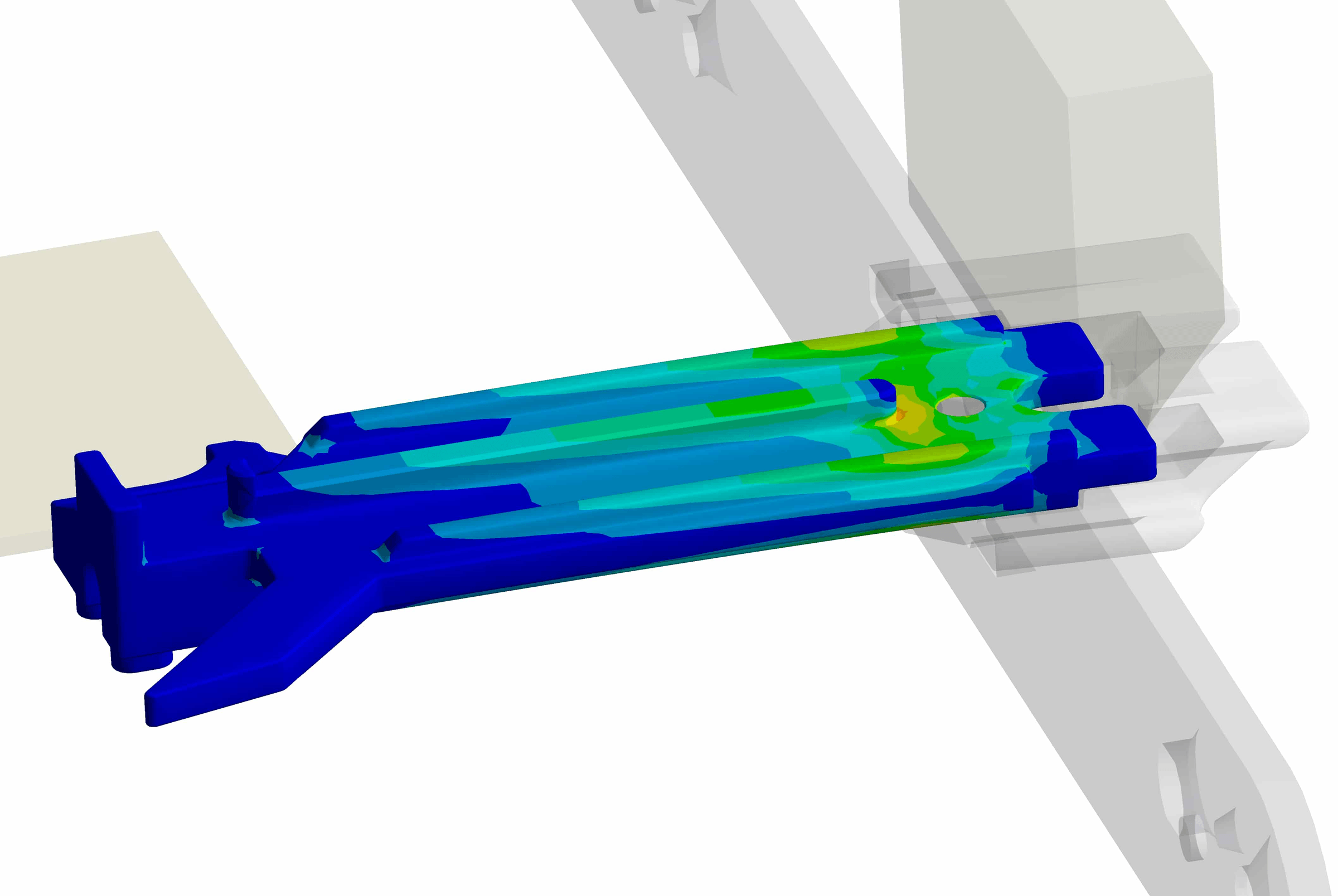

different directions. We performed a structural mechanical analysis using Finite Element Method (FEM) for two load cases (Figure 1). The critical parts that should withstand these forces are shown in Figure 2. Both load cases were simulated on the longer part in Figure 2 (right) and critical areas could be defined.

defining and improving high stress areas.

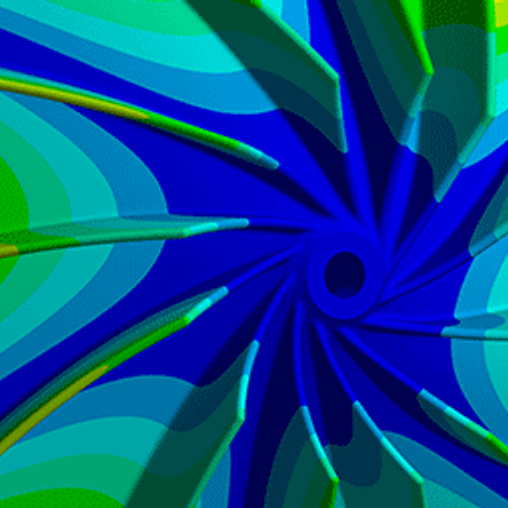

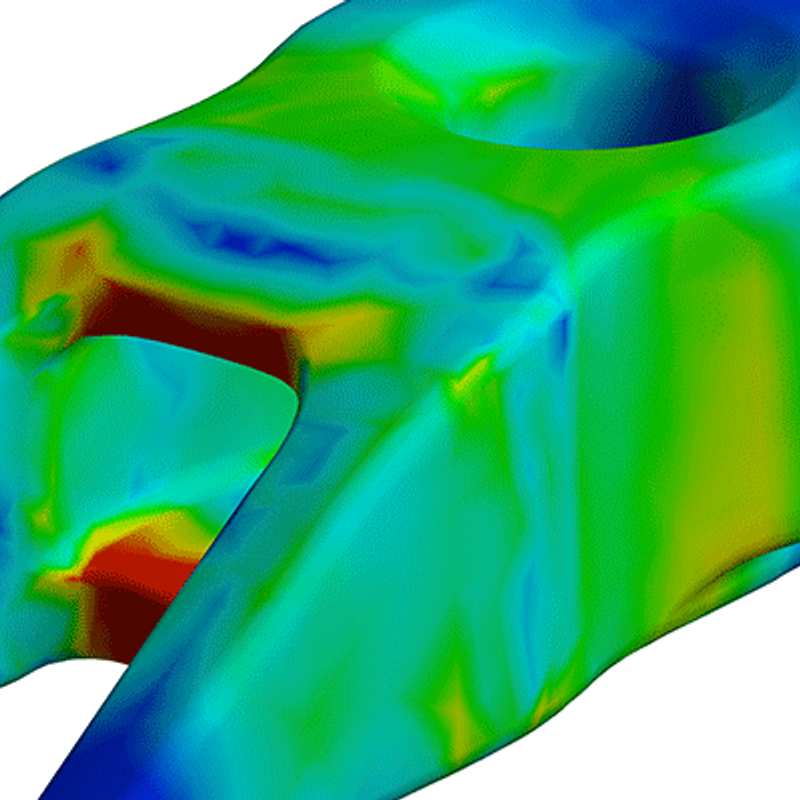

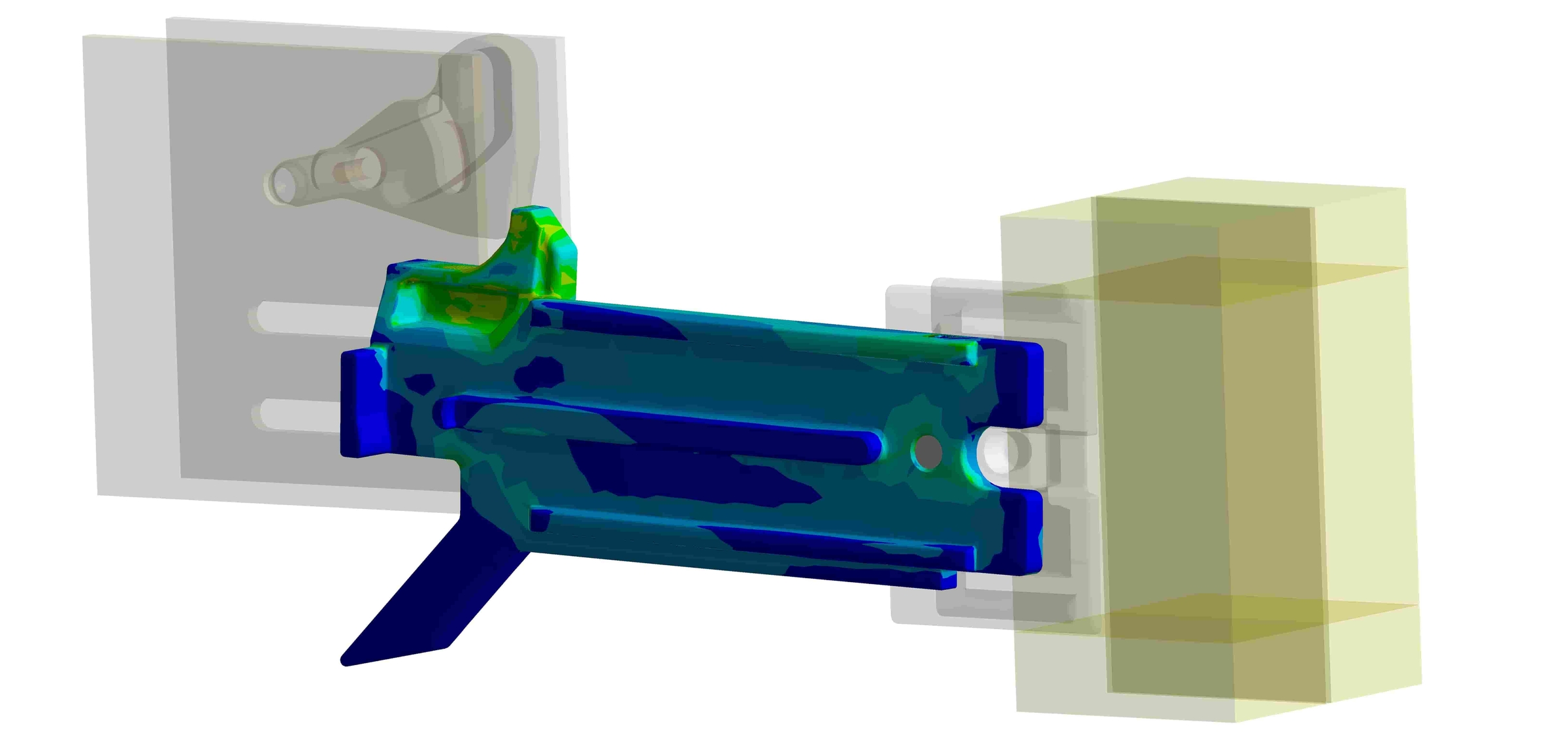

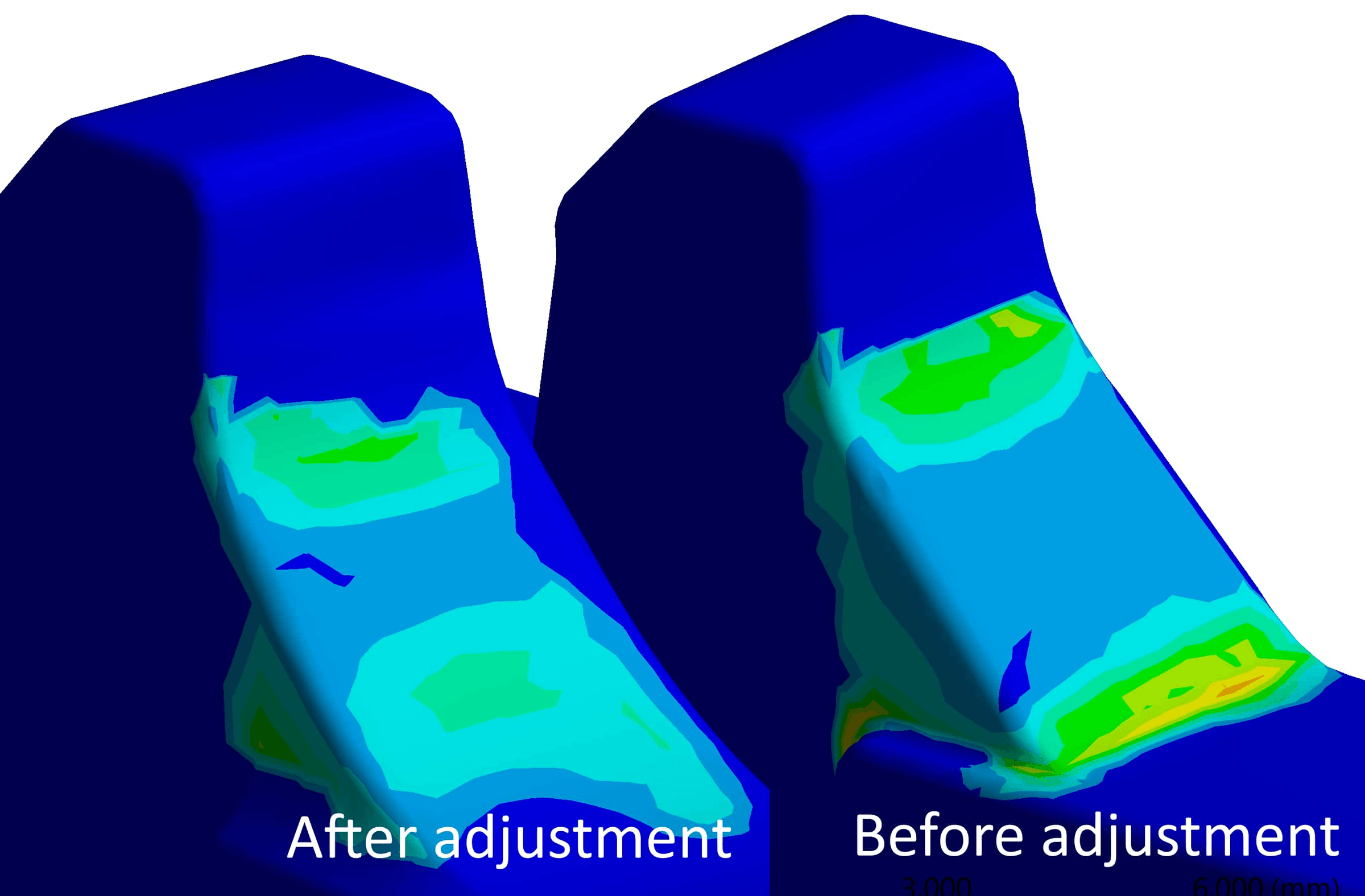

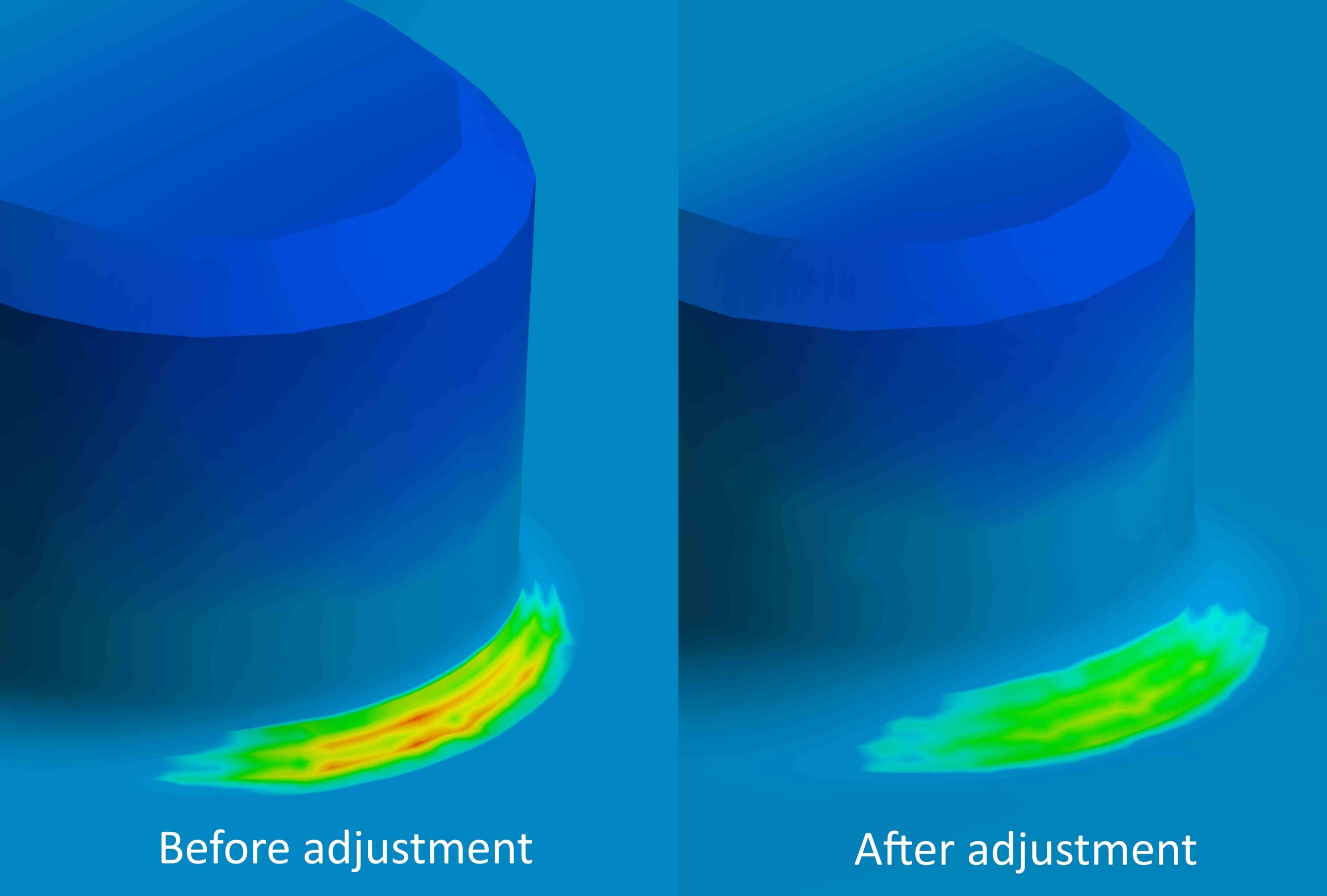

The results of the FEM analyses are shown in Figure 3 and 4. It can be seen that the area of the part that experiences the highest stress, is different for both load cases. The critical area for load case 1 is the connection point between the shaft and the locking mechanism and load case 2 creates a critical area on the shaft that is exerted into the door post.

The simulation of load case 1, with a force parallel to the door, showed that the forces on the connection of the shaft to the locking mechanism are large (Figure 5). A failure type was predicted for this load case and it was tested subsequently. An exact match between the force of failure in the experiments and simulations was found. The simulation of load case 2, with a force perpendicular to the door, showed that the highest stresses are on the middle rib of the shaft (Figure 6). Especially on the fillets at the base of the middle rib and the rest of the material the stresses can rise above the fracture limit. Again, an exact match between the force of failure in the experiments and simulations was found.

With the cause of fractures at ultimate load known, it was possible to propose improvements to the design. Reshaping the geometry at the critical areas of the geometry resulted in a significant reduction of the stresses. The customer performed tests on the improved lock, which confirmed that the new geometry could handle the specified load cases without breaking. The locks can now withstand a significantly higher load compared to the initial design. Finally, the proposed design changes were optimized for production by our sister company Demcon metal injection moulding and could directly be produced.

conclusion.

With the use of mechanical FEM analysis, we showed which parts of the lock are critical when it comes to fracturing. Improvements were proposed, which were validated using simulations. Do you have a mechanical problem which you would like to have simulated? Are you looking for advise on the mechanical design of your product? Please feel free to contact us!

As a Multiphysics engineer you encounter practical problems. We encounter doors every day and we trust that they do not easily break. With FEM we have a tool that can pinpoint us the weakest link in the chain. In this way our design process is sped up.