preventing cavitation.

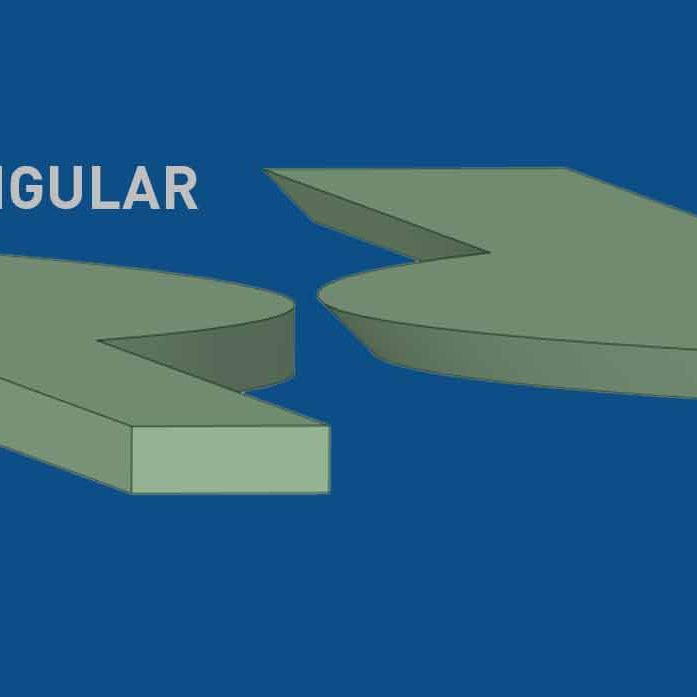

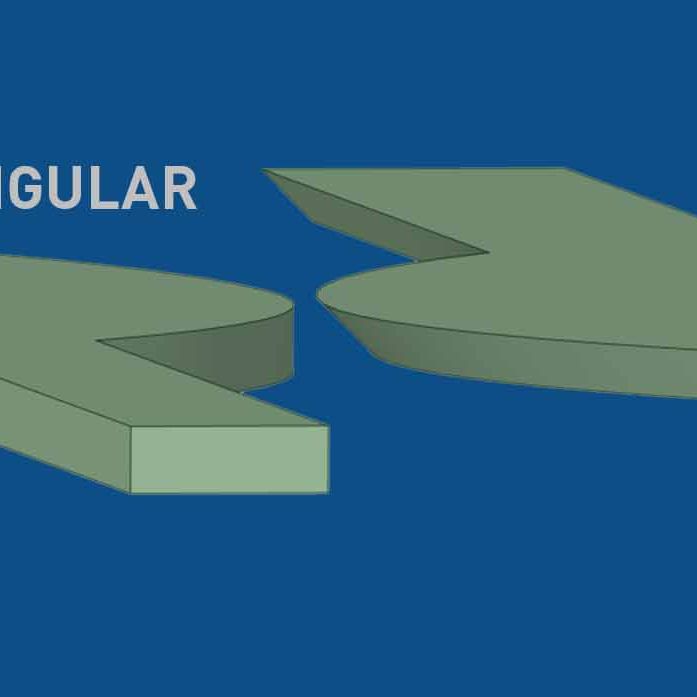

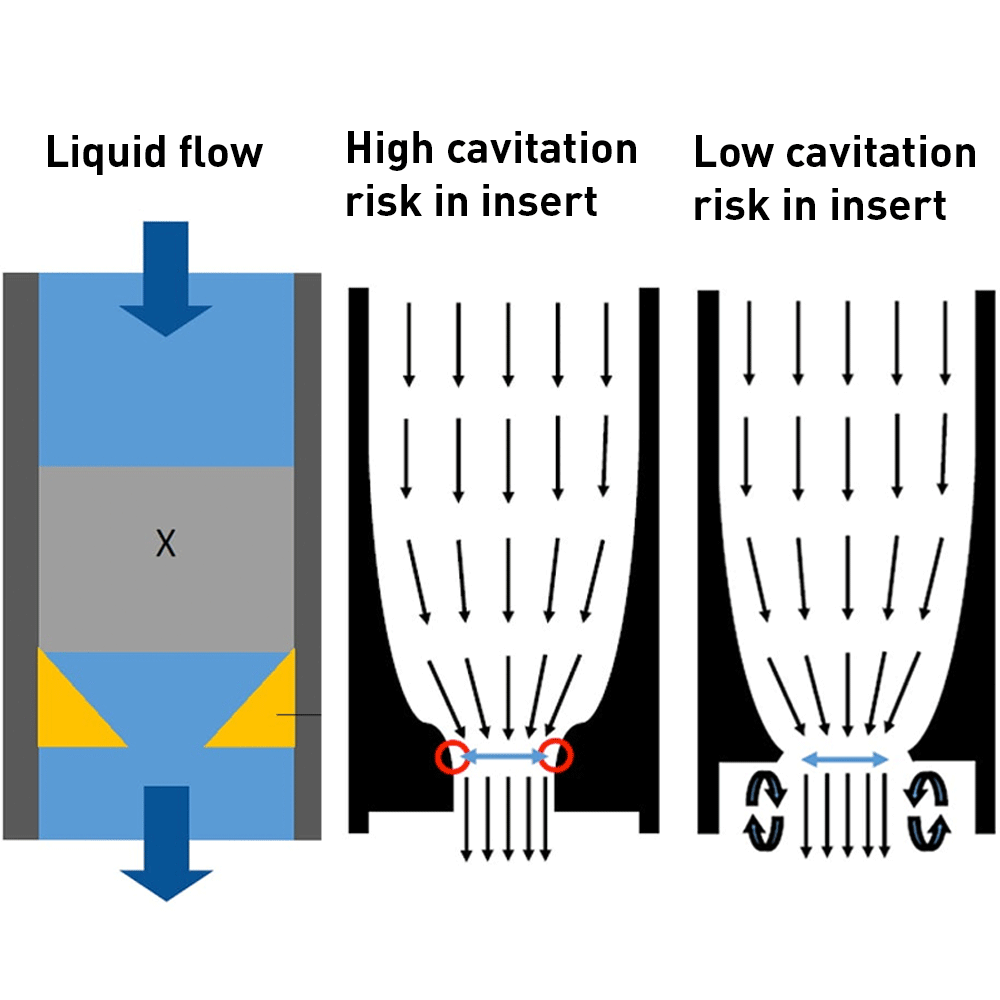

The design of such an insert is not trivial as it has to meet the following requirements: It must prevent cavitation near region X, it must not cause cavitation itself, it must allow the cooling flow to continue and it must be (relatively) cost effective to manufacture.

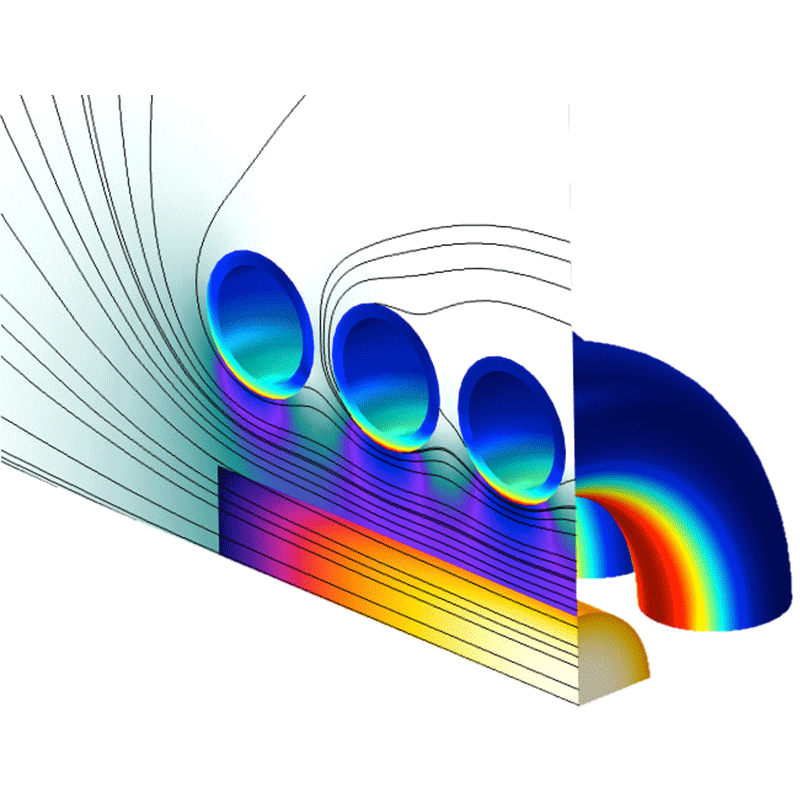

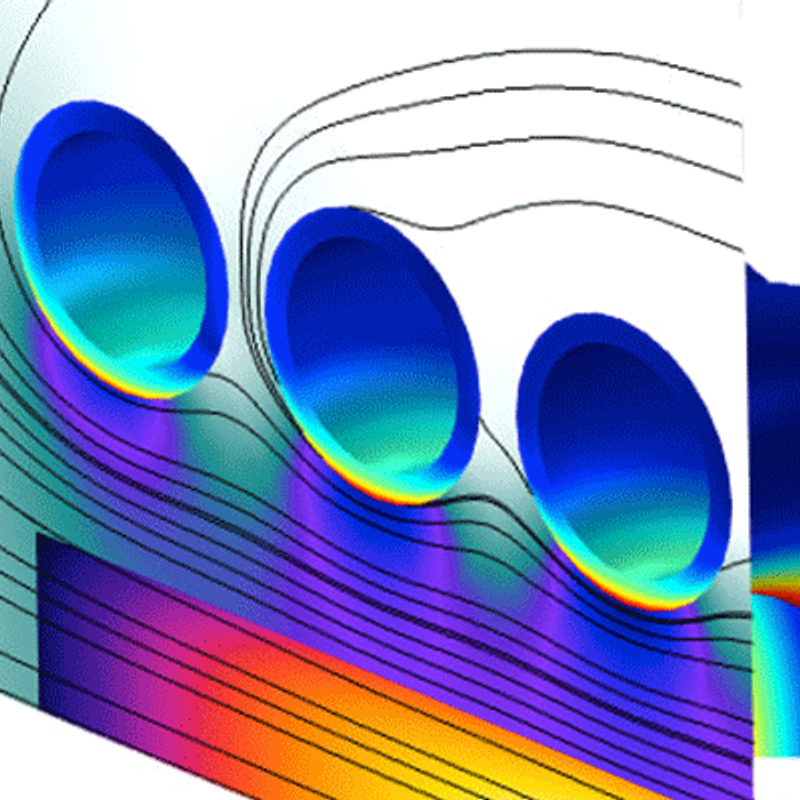

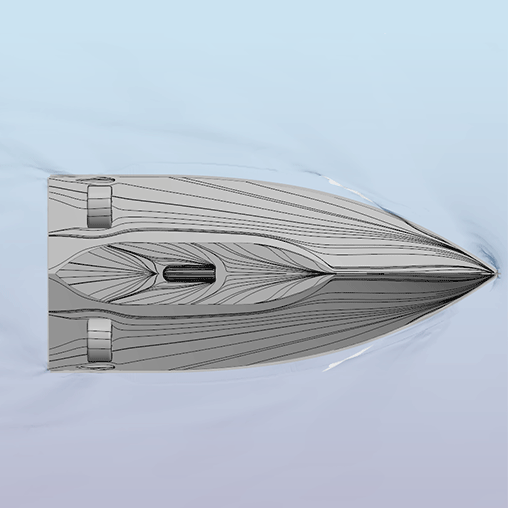

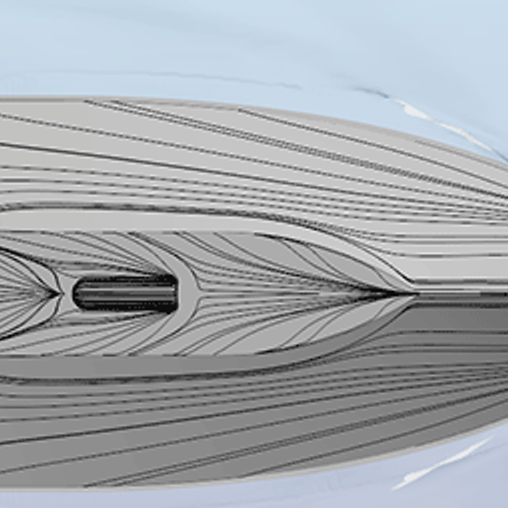

Preventing cavitation can be achieved by increasing the downstream pressure of the system. A well designed converging insert increases the pressure upstream of the insert, removing the risk of cavitation near the important parts of the system. To prevent cavitation and choked flow caused by the insert itself, the design should theoretically not have pressure decreases near a wall, but instead in the fluid layer. This will allow for a circulation of the cooling liquid, preventing a local pressure decrease. The red circles in the figure mark the risk area for a poorly designed insert, in which the point with the lowest static pressure is close to the wall. If this point is located in the liquid behind the nozzle, the low pressure can be prevented through circulation of the liquid.

To validate this concept, two insert designs are taken and compared numerically as well as experimentally. For both designs, a CFD simulation was setup and compared to an representative experiment.

"computational and experimental"

Combining CFD with experimental research allows for any flow or thermal related question to be answered. Despite the many challenges in matching the two fields, it is very rewarding once the computational prediction matches the experimental result. Additionally, the insight in the fluid mechanics visible in computational results allows for a deep understanding of the fluid flows, which wouldn’t be visible in an experiment.

Herausforderungen, die wir meistern.

Demcon multiphysics.

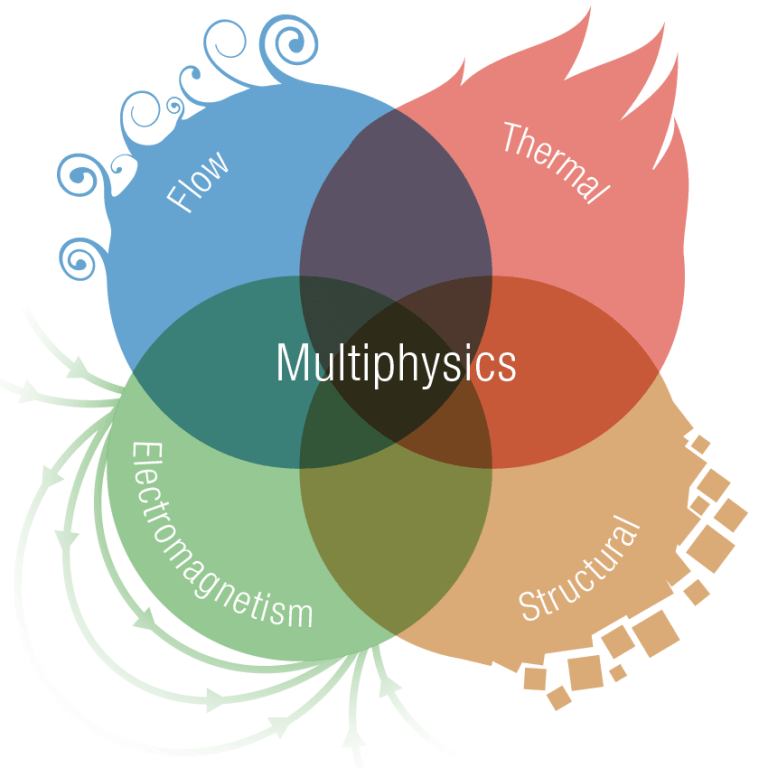

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.