operational capabilities of ships.

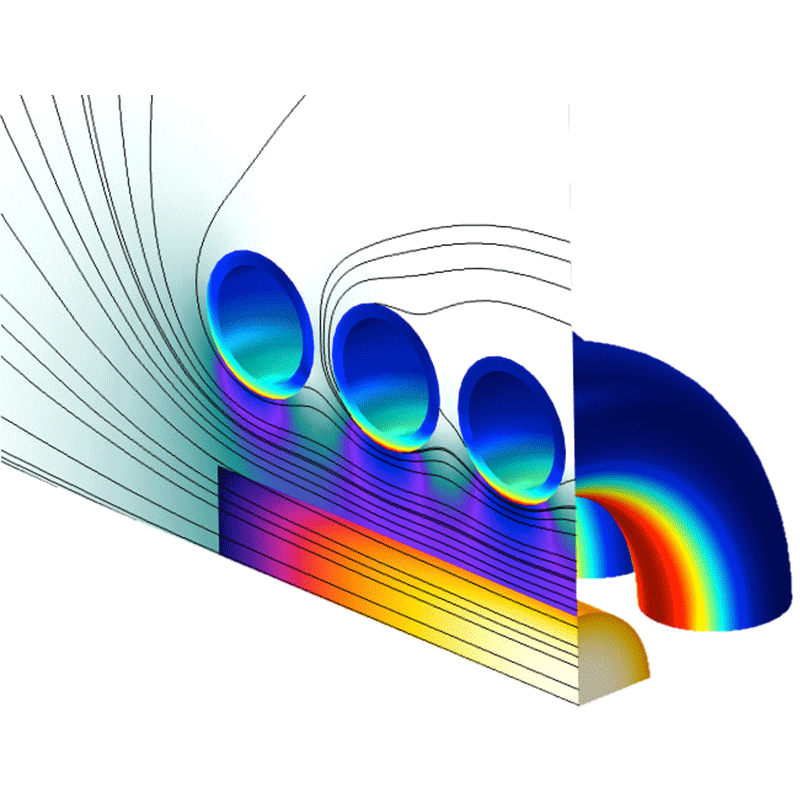

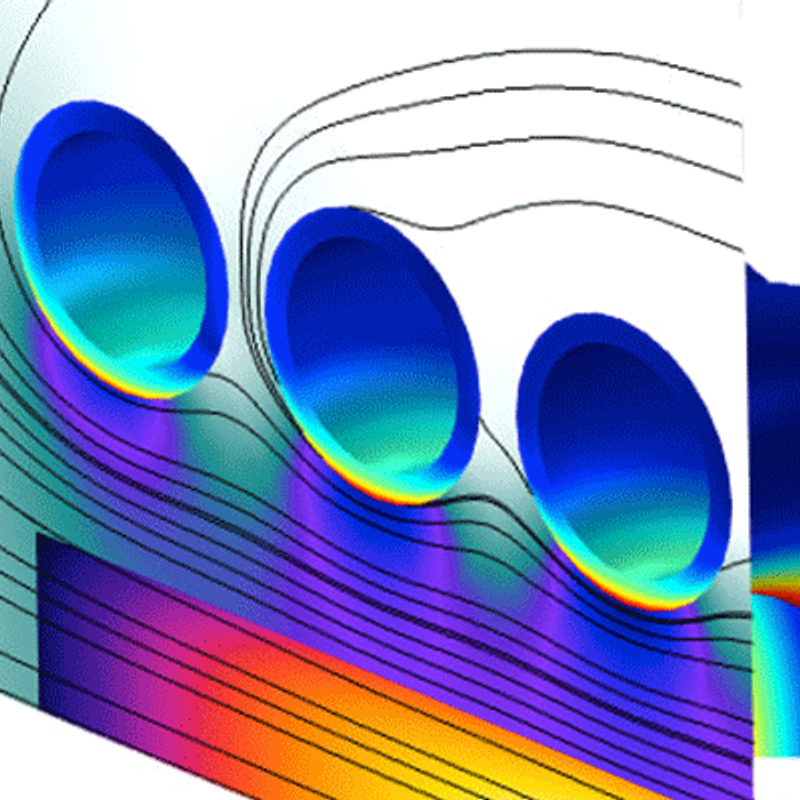

The panel method, known for its numerical efficiency, is commonly used for seakeeping calculations. However, this method assumes an irrotational flow and neglects viscosity, limiting its ability to provide detailed flow insights around the vessel. To achieve more accurate results, especially in capturing effects like viscosity, damping, and turbulence, a CFD simulation is preferred, albeit with longer computation times.

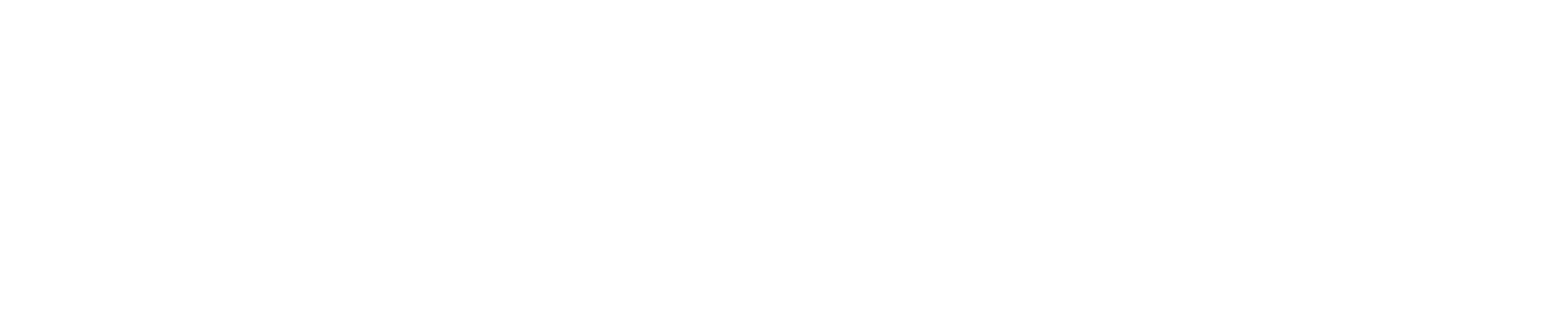

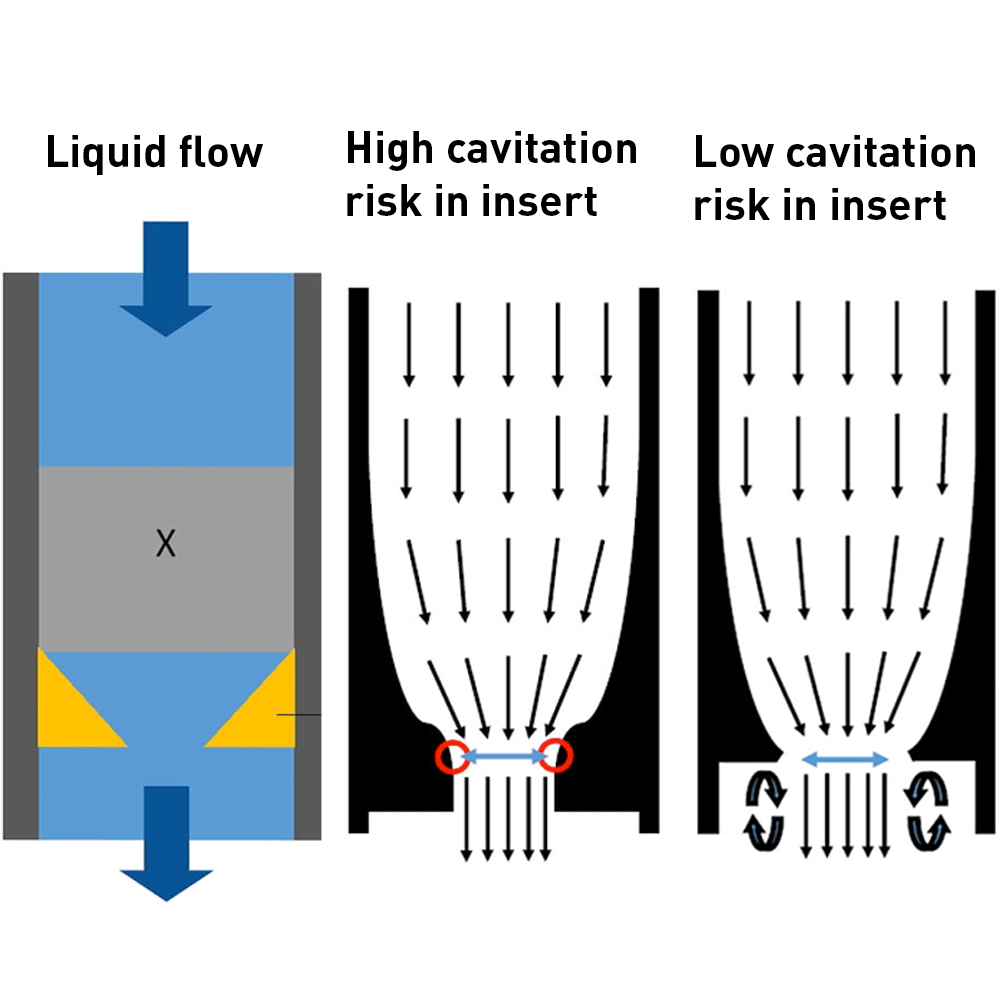

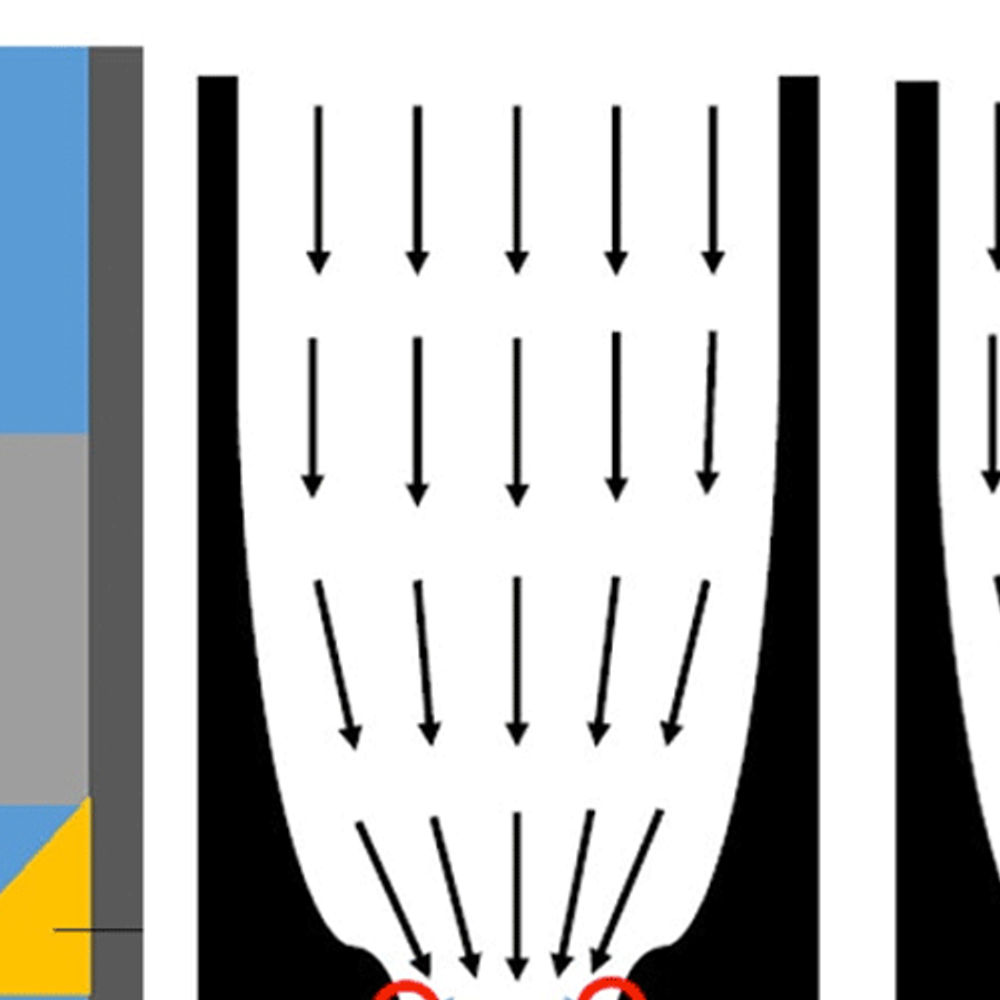

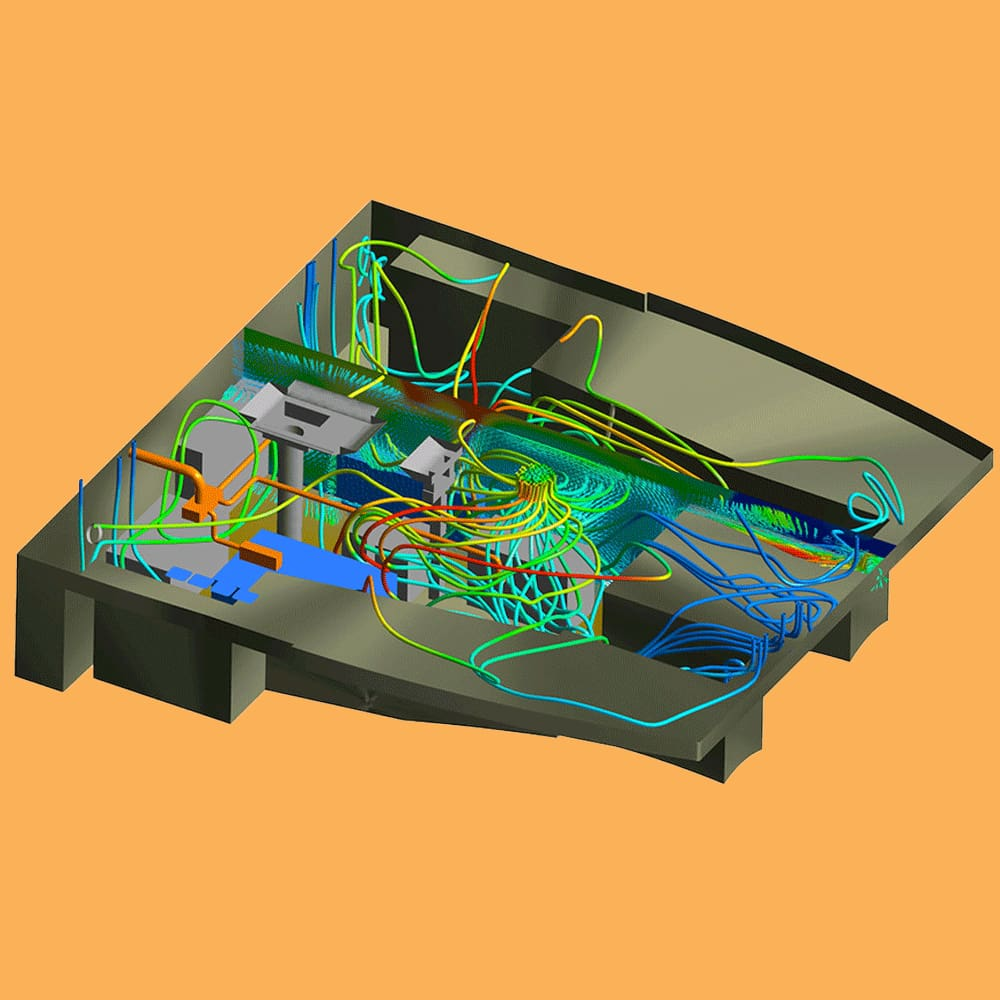

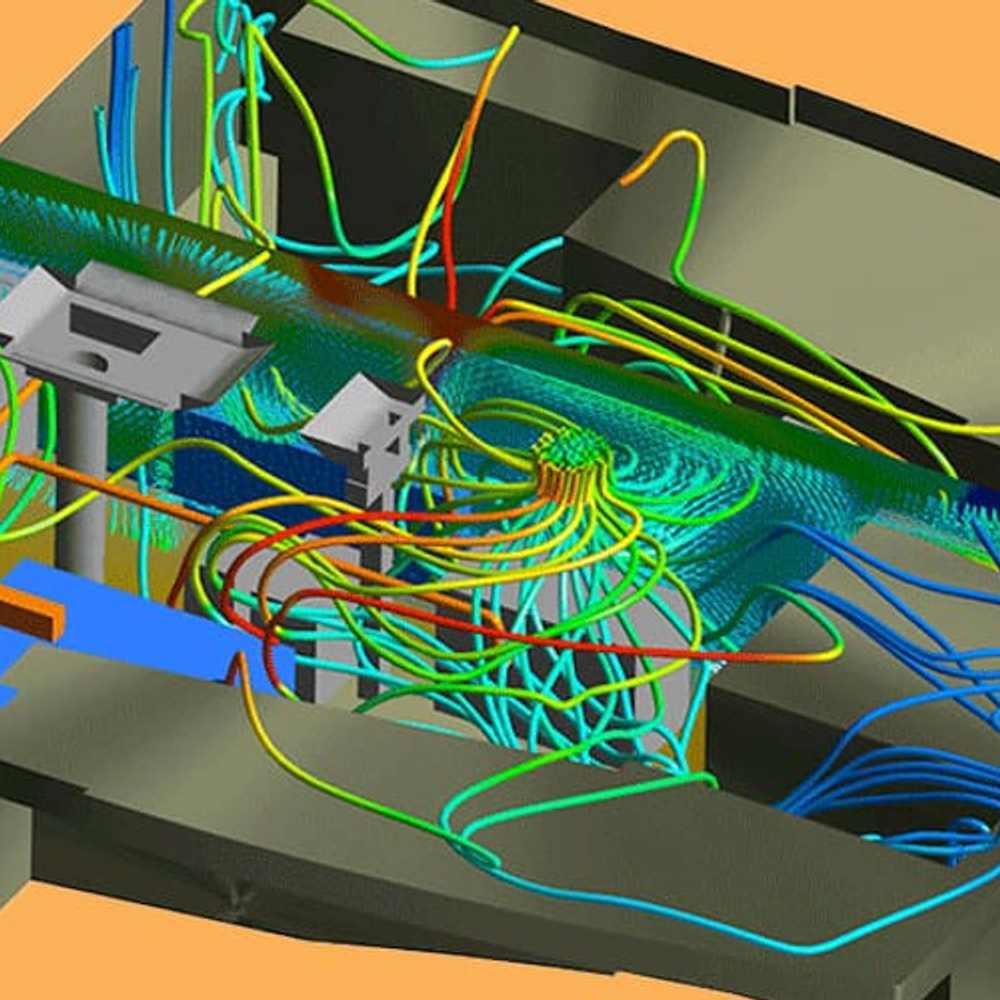

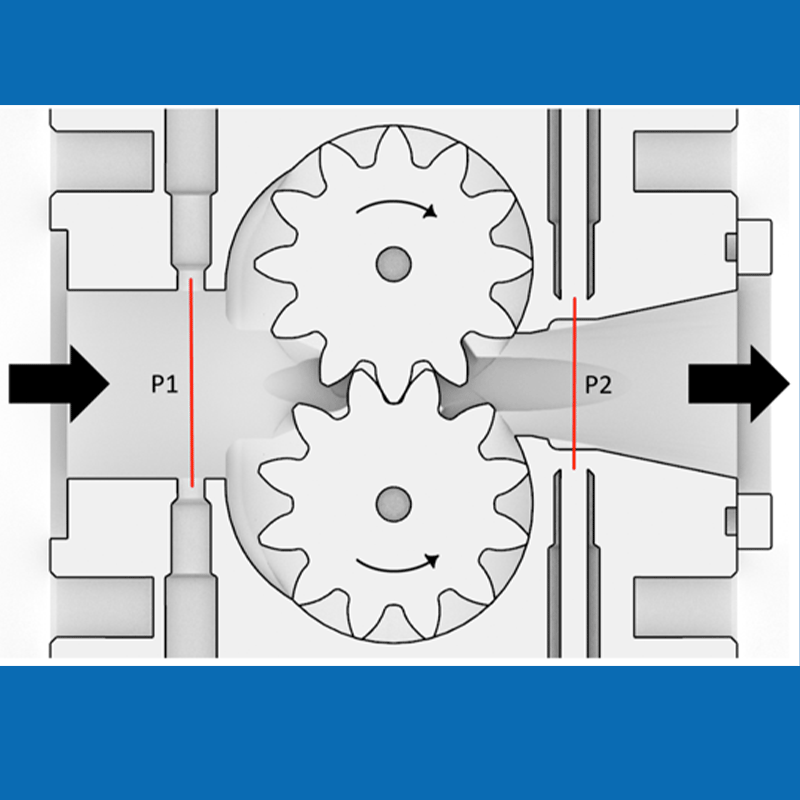

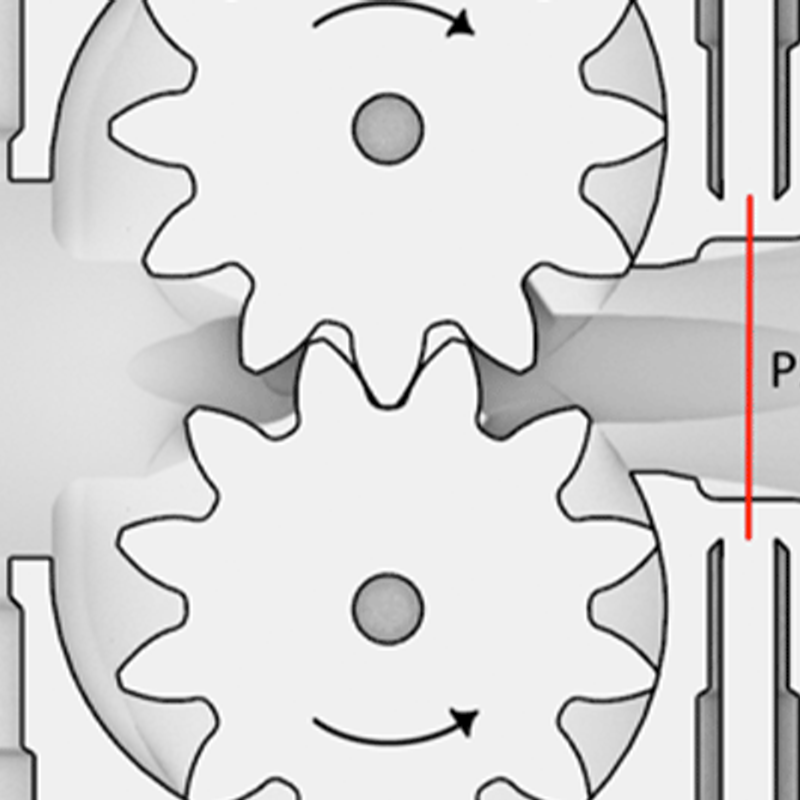

To assess air entrapment beneath the vessel, a CFD analysis was conducted, simulating the vessel sailing into a regular wave with a height of 1 meter. This analysis used a Volume of Fluids (VOF) approach, which tracks two components—air and seawater—throughout the simulation, with each cell containing a fraction of each component. The vessel was given two degrees of freedom: pitch (rotation around the y-axis) and heave (movement along the z-axis). The overset mesh approach accounted for the movement of the vessel’s geometry within the mesh. To evaluate thruster orientation, a steady-state resistance calculation was performed, again allowing movement in pitch and heave. Surface flowlines were analyzed to determine optimal thruster orientation. For assessing roll damping, a transient calculation was carried out by releasing the vessel from an inclined position, with the vessel having two degrees of freedom: roll (rotation around the x-axis) and heave. Using the insights gained from these simulations, DUS was able to refine the design of the V2500 (3M) USV, enhancing its performance in varying sea conditions.

Herausforderungen, die wir meistern.

Demcon multiphysics.

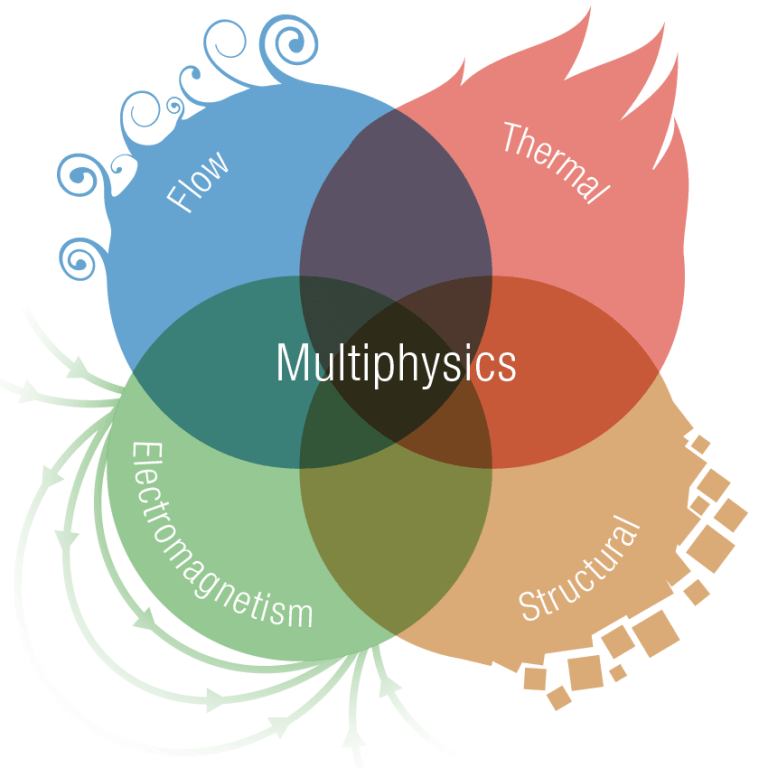

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.