Thermal engineering

EFI OptiGrip – thermal simulations to avoid overheating.

With keyhole surgery, thin tubes enter the body via small incisions. Grippers on the tip of these tubes manipulate the body tissue, and a small camera enables the surgeon to visualize what the grippers are doing. However, traditional keyhole surgery instruments lack haptic feedback – the feeling of resistance with your fingers when you grip something. DEMCON co-developed the OptiGrip: a sensitive instrument for keyhole surgeries with haptic feedback, where DEMCON Multiphysics assisted in the thermal design of the EFI OptiGrip to ensure that the design complied with all thermal specifications. Currently, this instrument is commercially available.

Controlling heat transfer

our approach.

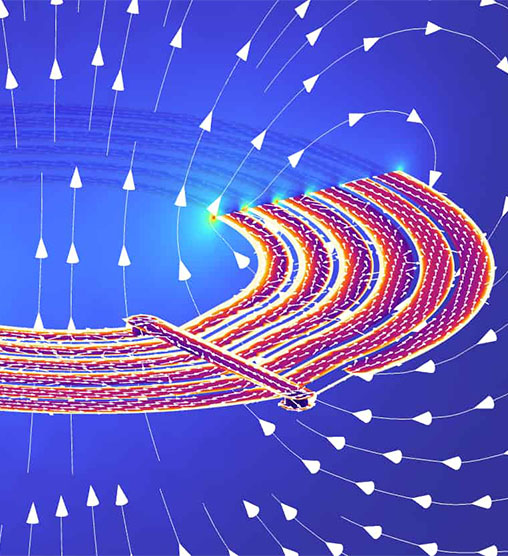

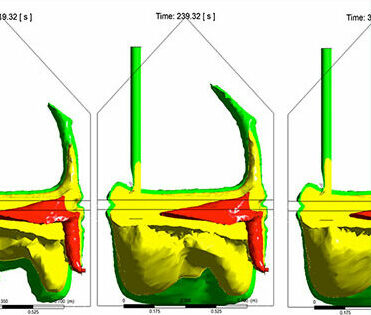

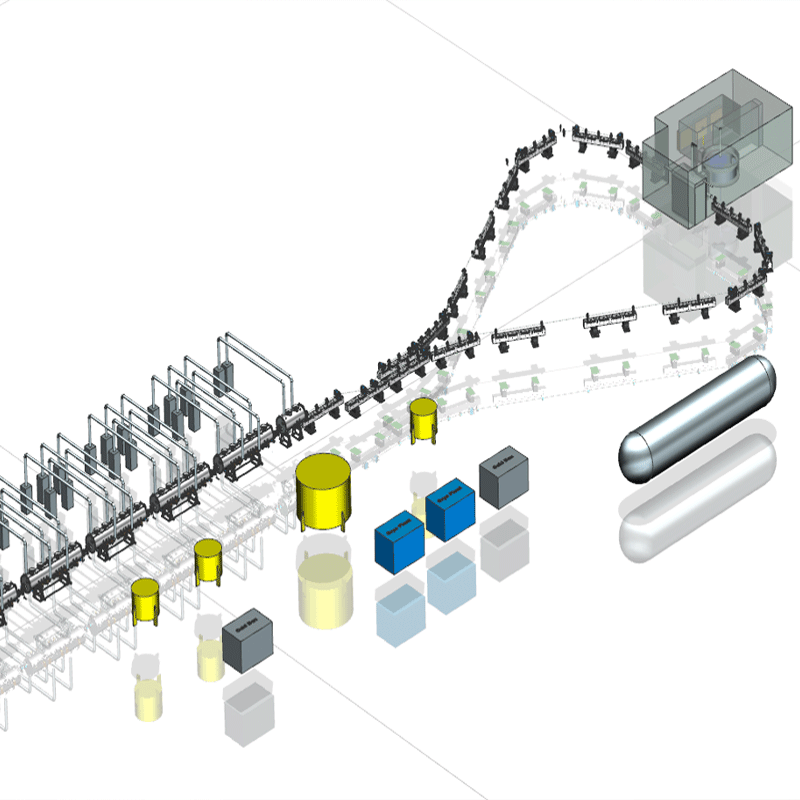

Using computation fluid dynamics (CFD) simulations, we calculated heat transfer in the instrument, while focusing on the casing, the handle, and the motor temperatures. We combined fluid flow and heat conduction through structural parts, using a so-called conjugate convective heat transfer model. Initial simulations showed clear room for improvement, and several design iterations were needed to ensure sufficient heat transfer towards the environment. To calculate the warm-up and cool-down times, we made use of transient simulations, as shown in the video.

Demcon multiphysics.

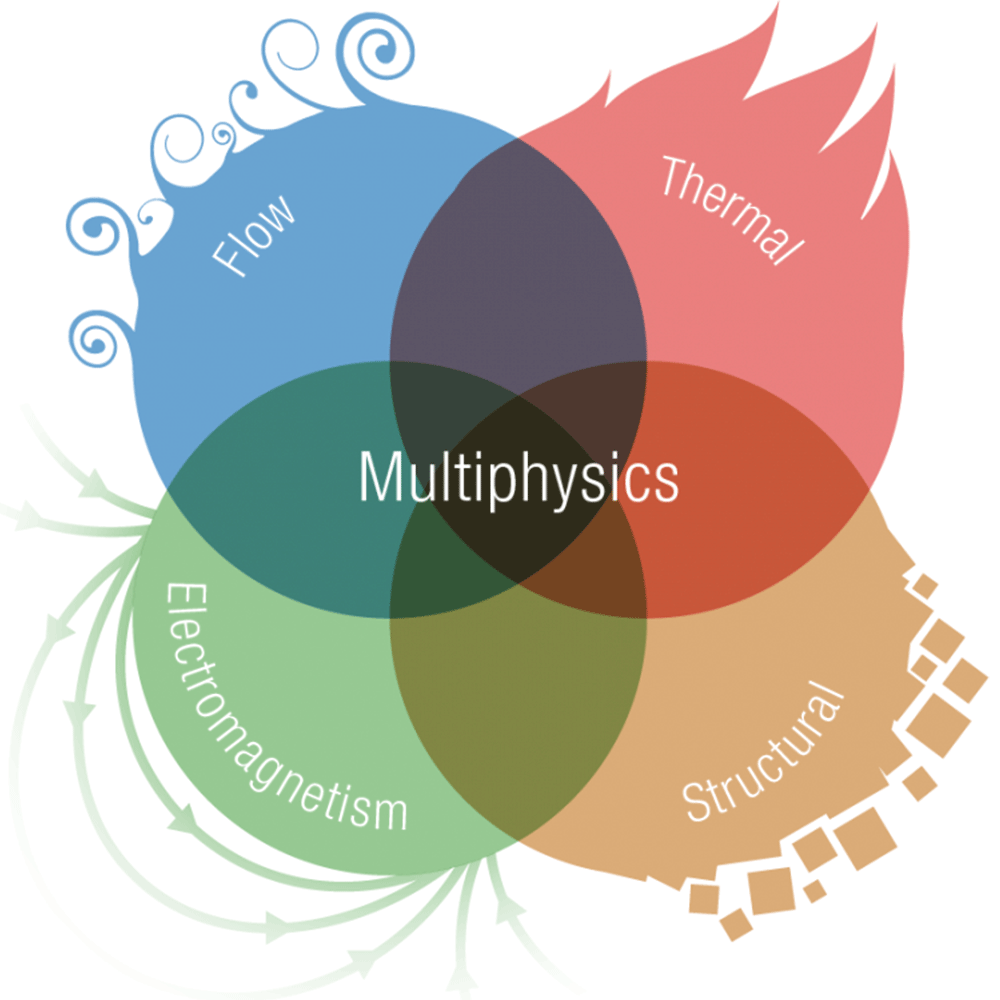

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.