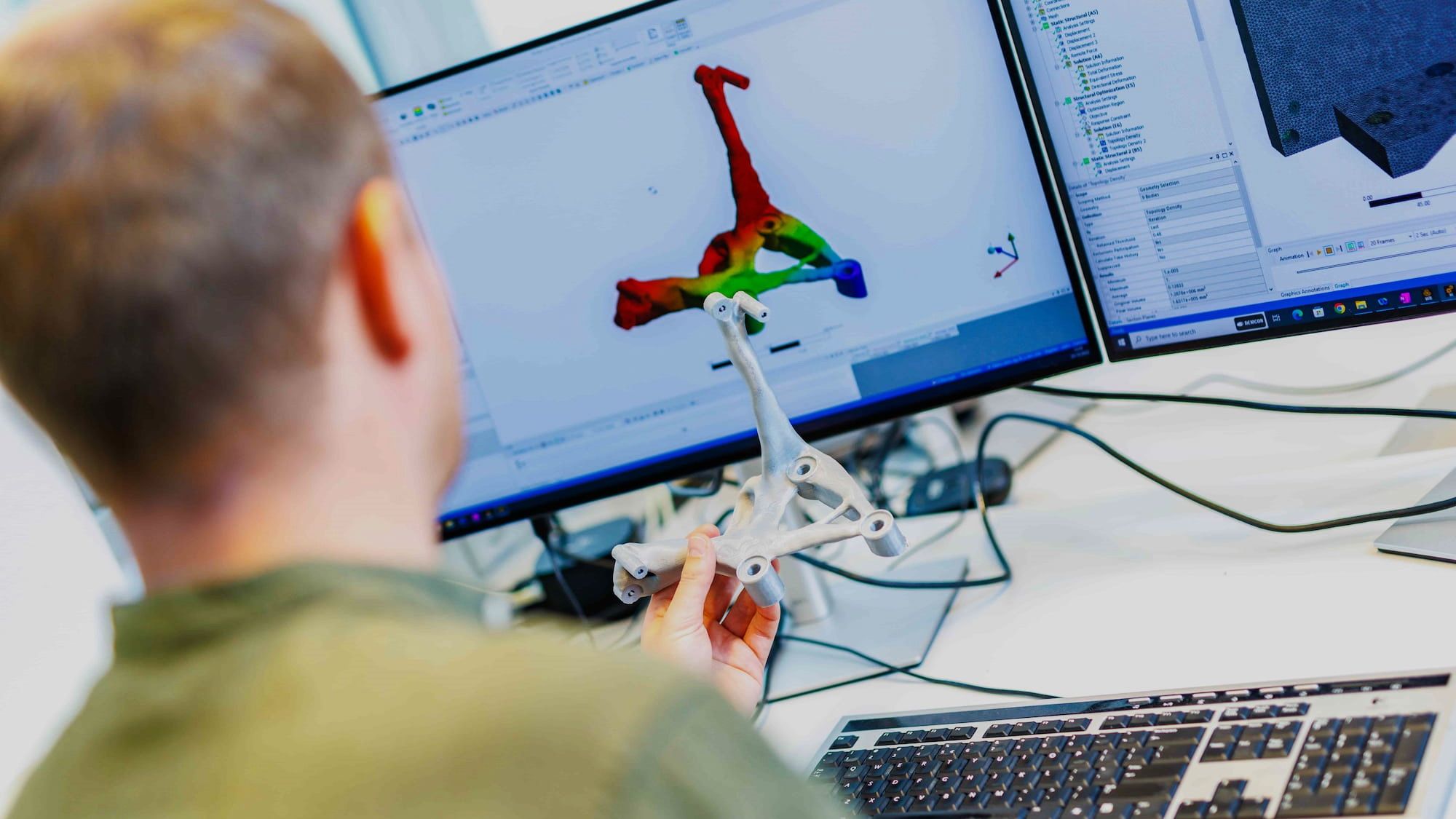

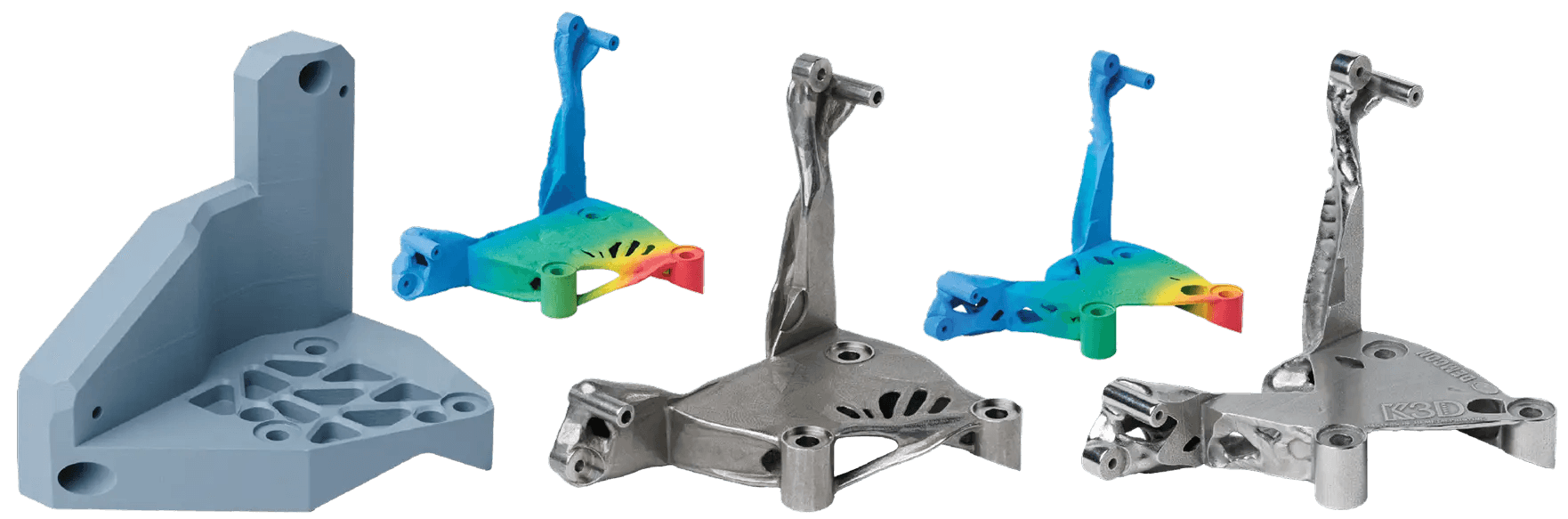

A lighter design by further removing material from the heavy part would make the part costly to be produced by milling. The possibility of producing it by 3D printing would therefore be a suitable option. It offers the possibility of free form shaping at a much lower cost and providing a high performance.

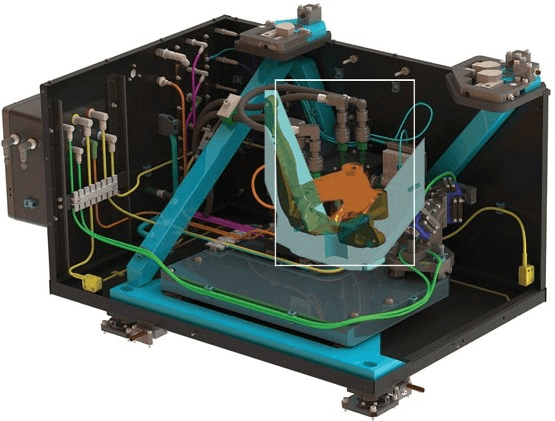

Demcon and K3D worked together to design a new part. It was aimed at designing a lighter part using the topology optimization method and looking critically in reducing the costs of the part. In a fruitful collaboration between Demcon and K3D a new part is designed.

design proces.

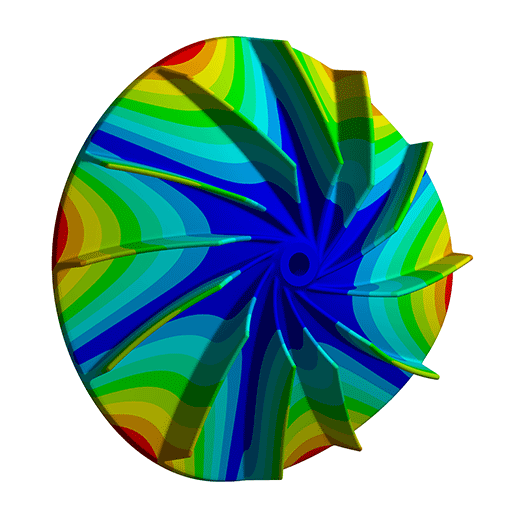

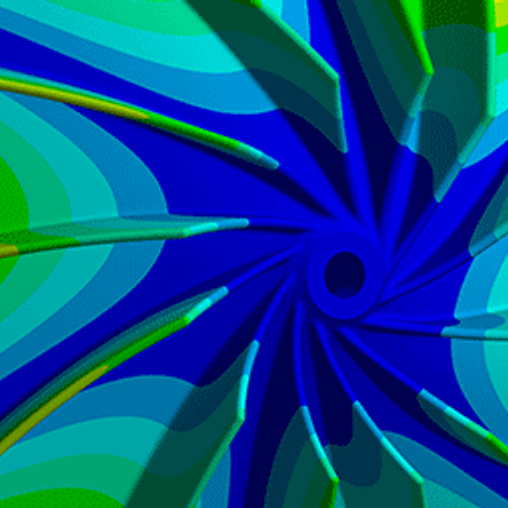

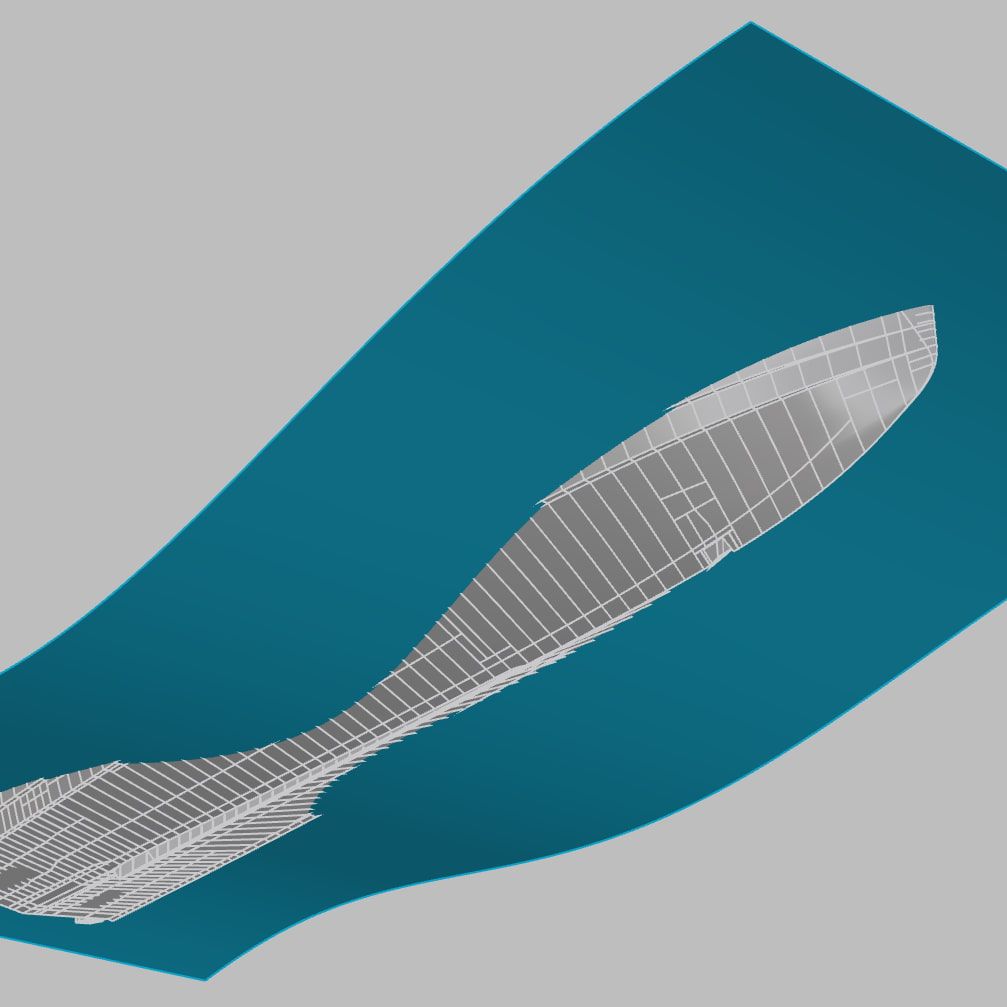

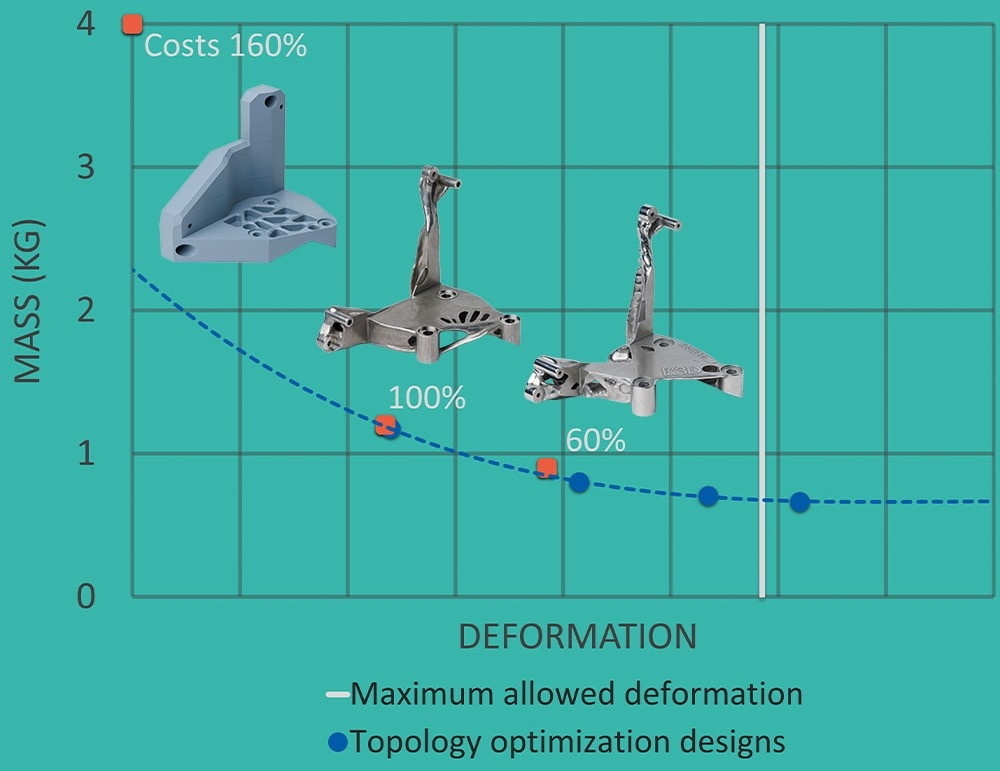

A lower limit was specified for the stiffness of the bracket together with its available space and connection points. This means a limit on the maximum deformation. For the first design iteration the part was optimized using topology optimization considering 4 different loads.

The second design iteration was performed including extensive knowledge of K3D about the printing process. It was investigated how the part can be printed more efficiently without supports and allowing tinniest features of 0.3 mm within the design to get the highest performance. These constraints were included in the topology optimization solver.

For both iterations the computer did the designing process and generated shapes which comply with the given constraints.

realisation of 78% weight reduction.

The first design iteration resulted into a part where its stiffness was optimized for a given mass of 1.2 kg, having a weight reduction of 2.8 kg.

Second design iteration resulted into a final part of 0.9 kg, i.e., an additional mass reduction of 0.3 kg or 25%. Moreover, this iteration without printing supports resulted into 50% reduction of the material required for printing and 40% cost reduction.

This fruitful collaboration between DEMCON and K3D clearly shows how we can optimize your part in costs and performance.

Herausforderungen, die wir meistern.

Demcon multiphysics.

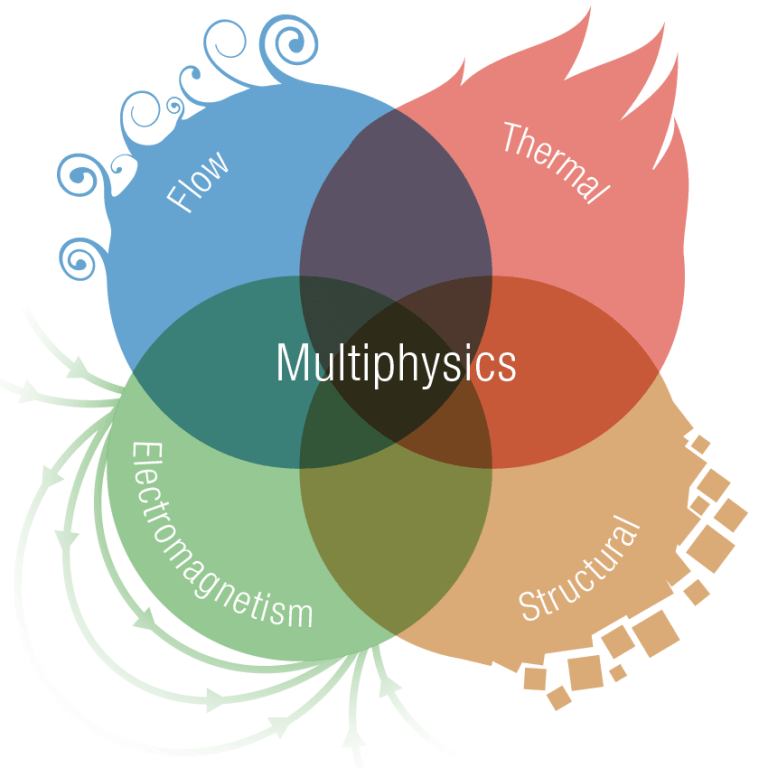

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.