Patients that require blood transfusions are at risk of hypothermia – a body core temperature below 35 °C. This risk is especially significant when the patient is in need of a large quantity of blood. Pre heating the blood before it is injected into the body could reduce this risk. However, the design of these heaters is complex due to the risk of degradation of red blood cells when trapped in a flow recirculation zone in the heater.

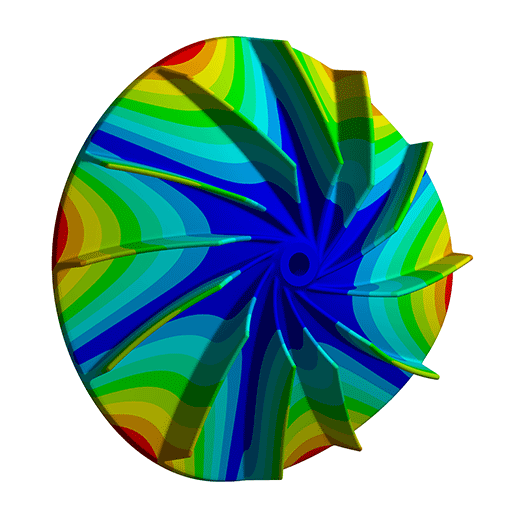

Hence, Demcon multiphysics was asked to help with the design of a geometry that minimized these recirculation zones. Blood is a very complex fluid to model, therefore, we uses a twofold approach. First, Computational Fluid Dynamics simulations were compared to experiments and the model was modified accordingly to capture the complex behavior of blood. Second, CFD simulations were performed to optimize the design of the heater. The optimized heater design was experimentally tested and resulted in a successful market introduction for our customer.

improving blood transfusions.

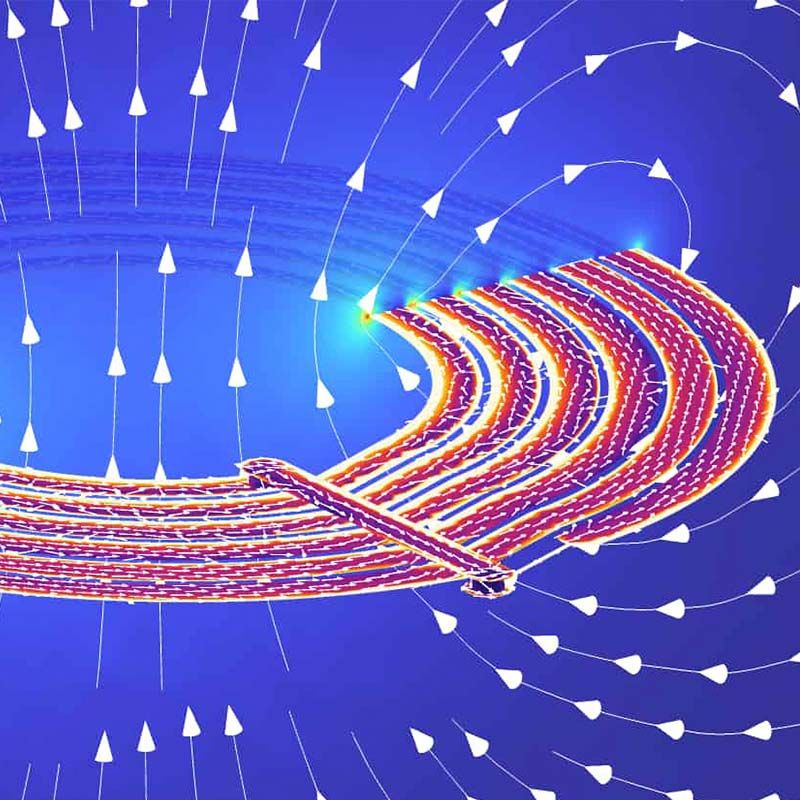

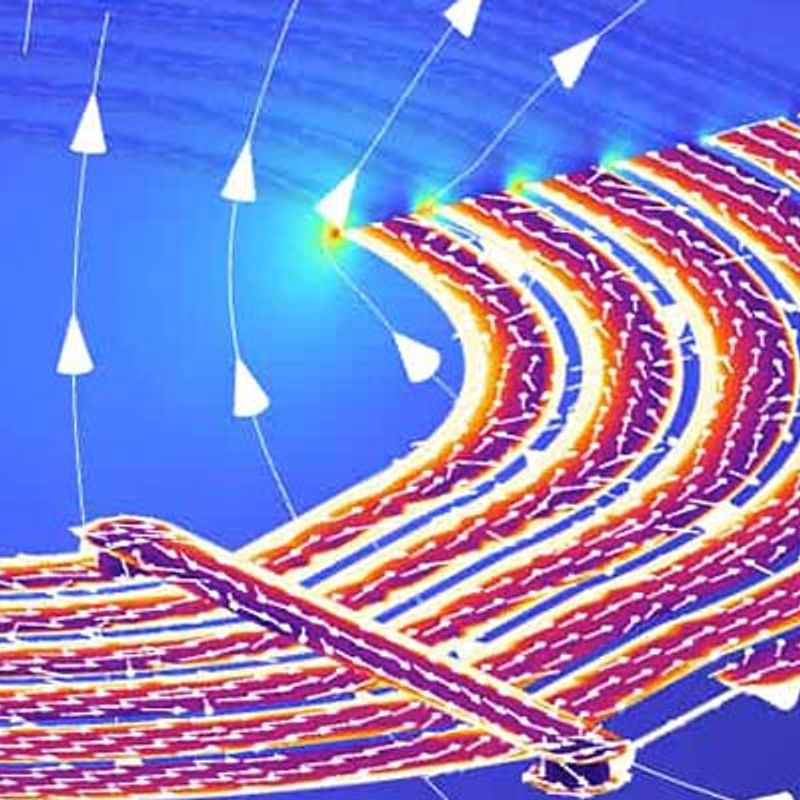

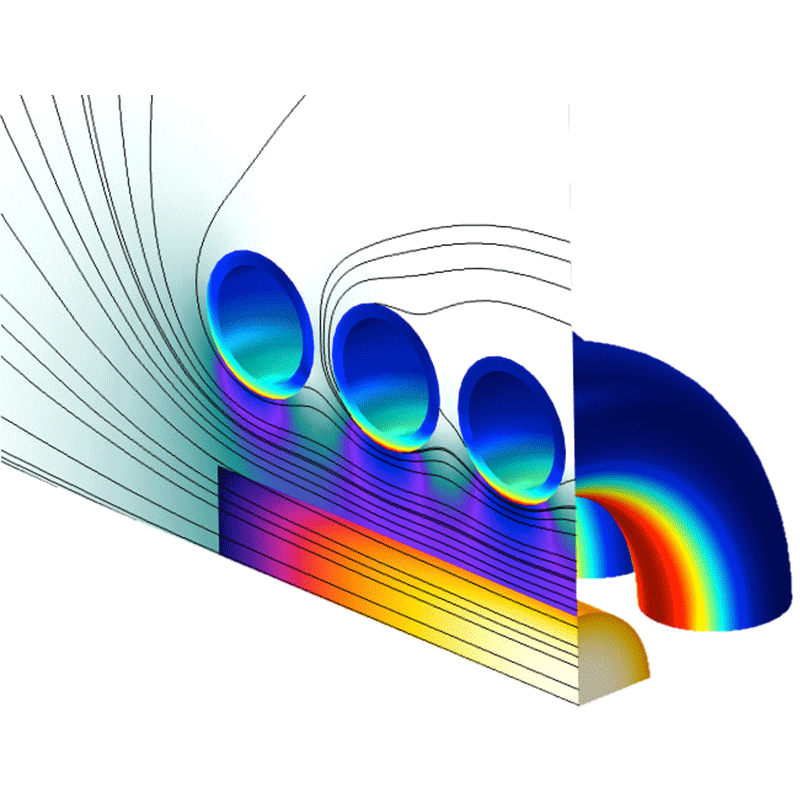

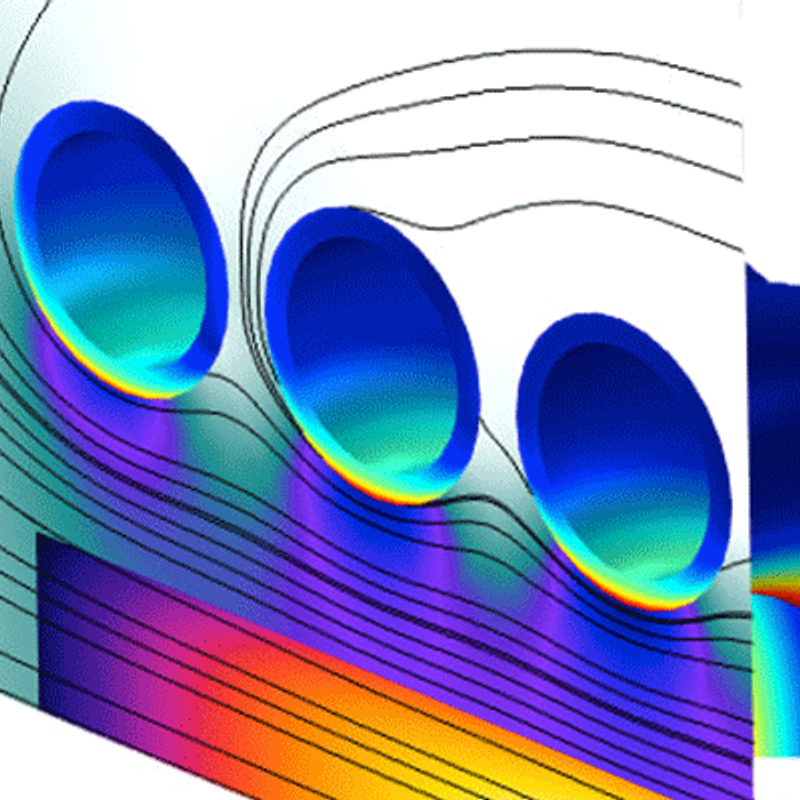

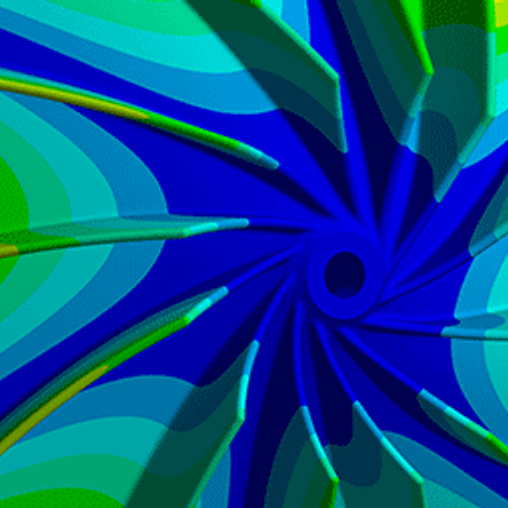

During the development of the blood heater it appeared that the flow pattern in the disposable is critical during the heating process. In previous experiments is was found that due to ‘dead’ zones and recirculation regions in the disposable, some red blood cells became too ‘hot’, leading to a risk of degradation of these blood cells.

In this study the geometry and the flow pattern of the disposable have been optimized, in order to remove these recirculation and dead zones and to improve mixing of the fluid. A main focus in this study is the reduction of the ‘dead’ zones in a single flow turn in the disposable.

The flow was optimized using CFD-calculations with the use of ANSYS CFX. We started with the comparison of CFD-results with experiments to obtain the correct settings for the CFD-calculations. Subsequent calculations were performed on geometries that were defined based on advancing insight.

Different geometries have been investigated. First the flow turn has been optimized such that the recirculation region disappeared. Subsequently, vanes have been added in the flow turn to improve mixing between cold and hot regions. As a criterium for the performance, the flow and temperature variance on the outlet area of the disposable have been used. In the final design, the flow and temperature variance have significantly been reduced. This is considered a major improvement.

Herausforderungen, die wir meistern.

Demcon multiphysics.

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.