Fluid Flow

modeling of a rotating mixing bag with a multiphase CFD model.

For the treatment of several diseases, different forms of cellular therapy are used. One way is to take cells from a patient’s body, cultivate them and insert them back into the patient’s body after sufficient growth. SCINUS Cell Expansion provides an innovative, controlled and cost-effective solution to automate cell culture processes. The SCINUS Cell Expansion system is a closed bioreactor system for the controlled cultivation of cells. Inside the bioreactor, the cells are kept in suspension in a liquid solution of nutrients, allowing these cells to multiply.

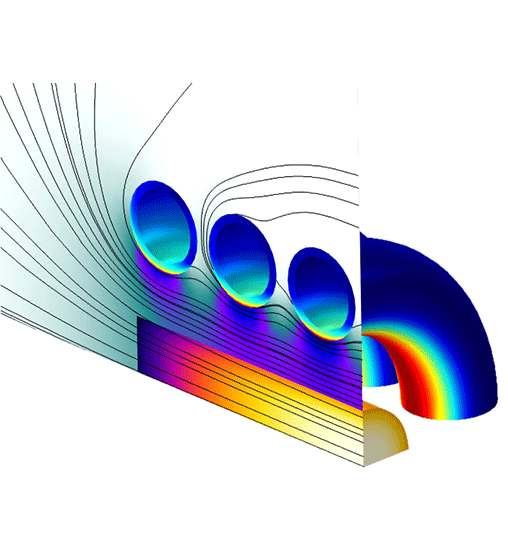

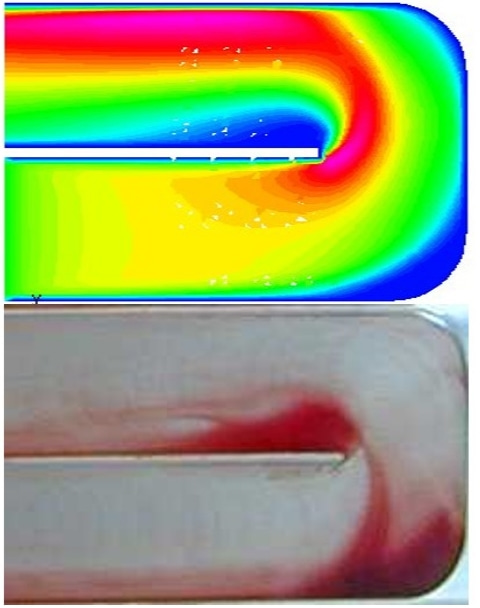

For optimal performance, sufficient mixing of the cells with nutrients is required. This is achieved by periodically rotating the reactor vessel, which leads to circulating flow inside the vessel. The process continues until sufficient multiplication has taken place. Here, we modeled the behavior of the suspension in the bioreactor and optimized the rotating movement to achieve optimal mixing.

mixing

our approach.

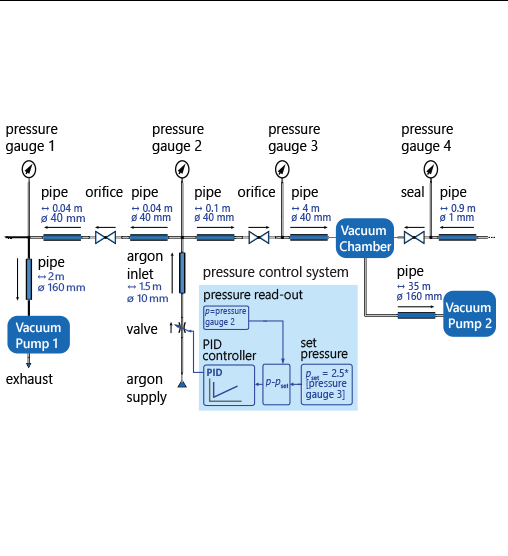

Accurate modeling of the behavior of the suspension in the bioreactor is required to optimize the cultivation process. The cells were modeled as small solid particles. The so-called mixture model was selected as an appropriate multiphase model for this system. The rotation of the reactor was modelled with Ansys CFX’s ‘Rotating domain’ option, which uses the rotational speed as function of time as input parameter. Although the bag is 3D, the mixing behaves largely in a 2D manner, so a 2D approach was chosen. Using a sensitivity analysis, several rotational patterns were investigated to optimize the mixing behavior.

Demcon multiphysics.

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

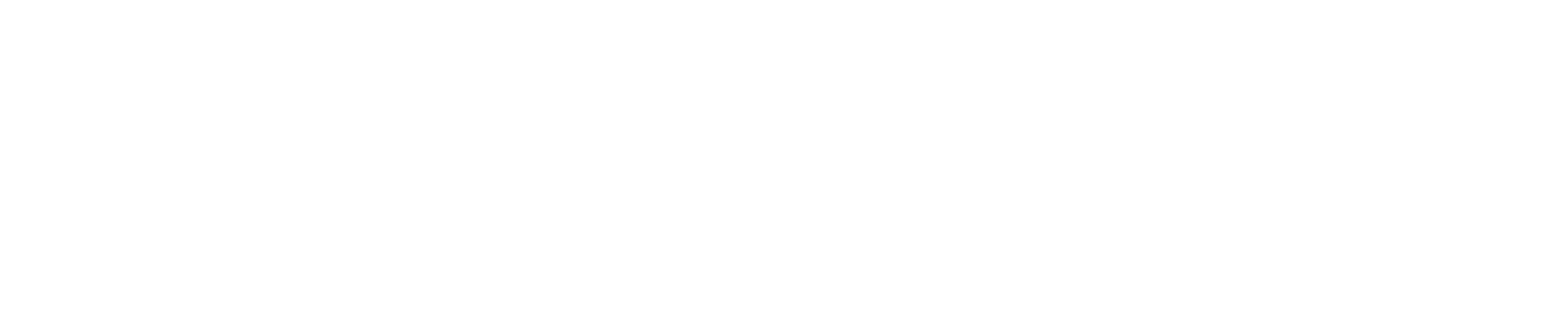

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.