radiation release.

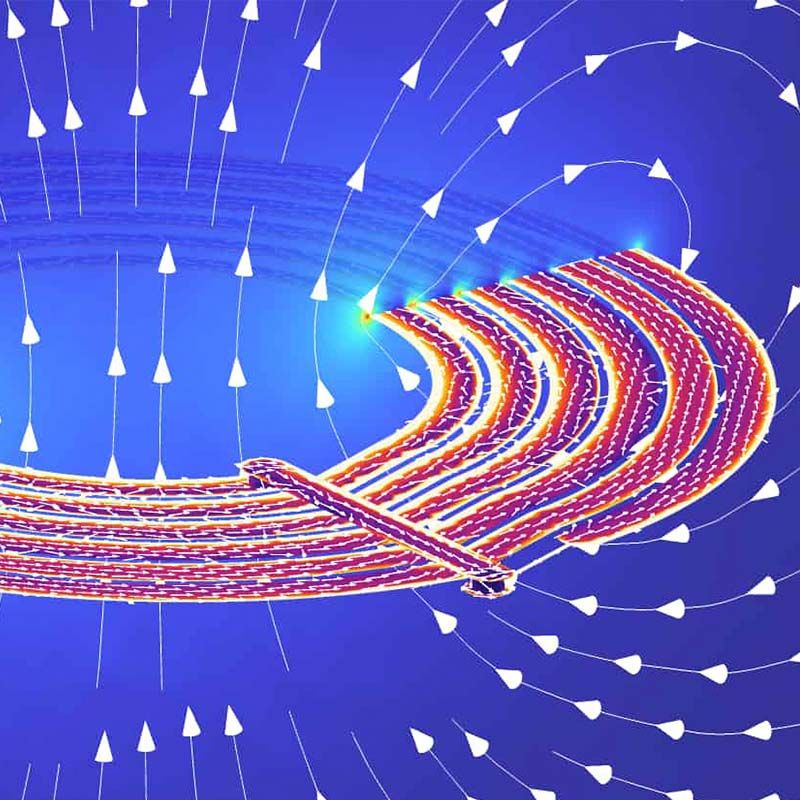

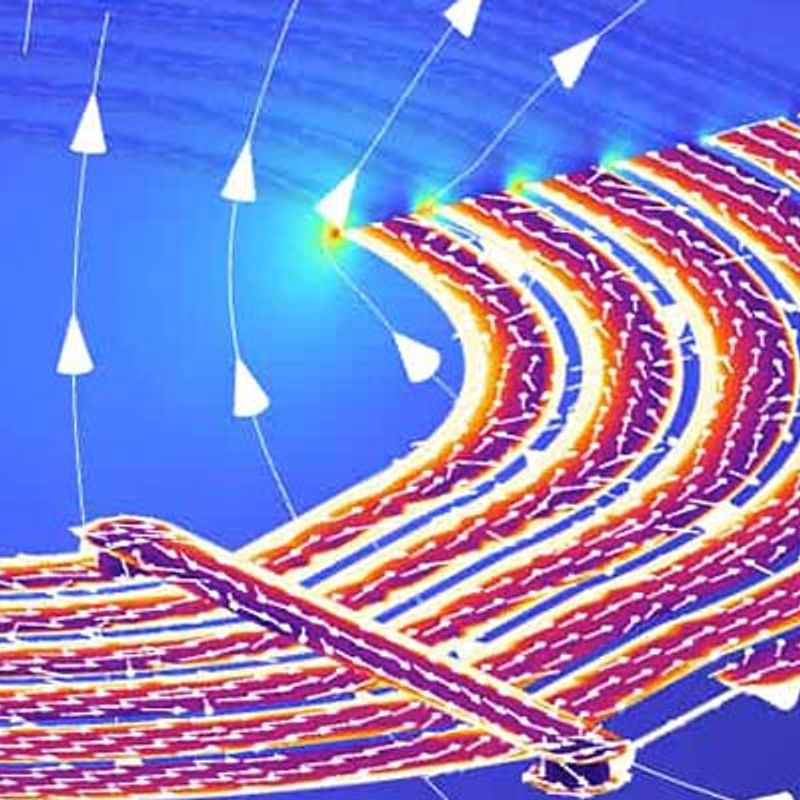

1. Simulate radiation environment

This captures all relevant information, such as neutron and photon energy spectra and distribution. This drives decisions on the shielding design.

2. Design shielding

We choose proper materials and thicknesses based on the radiation spectra.

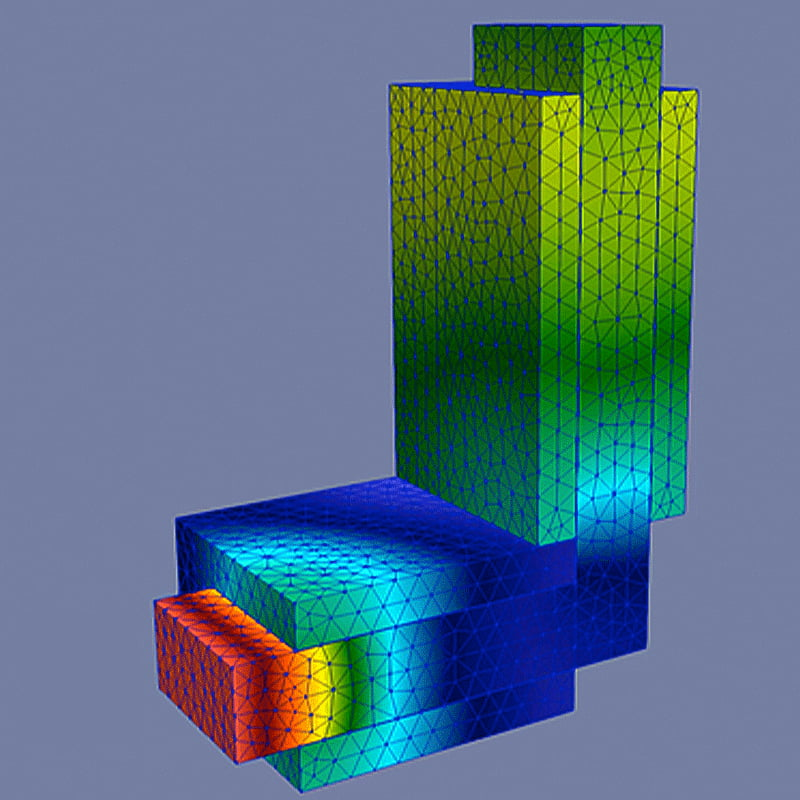

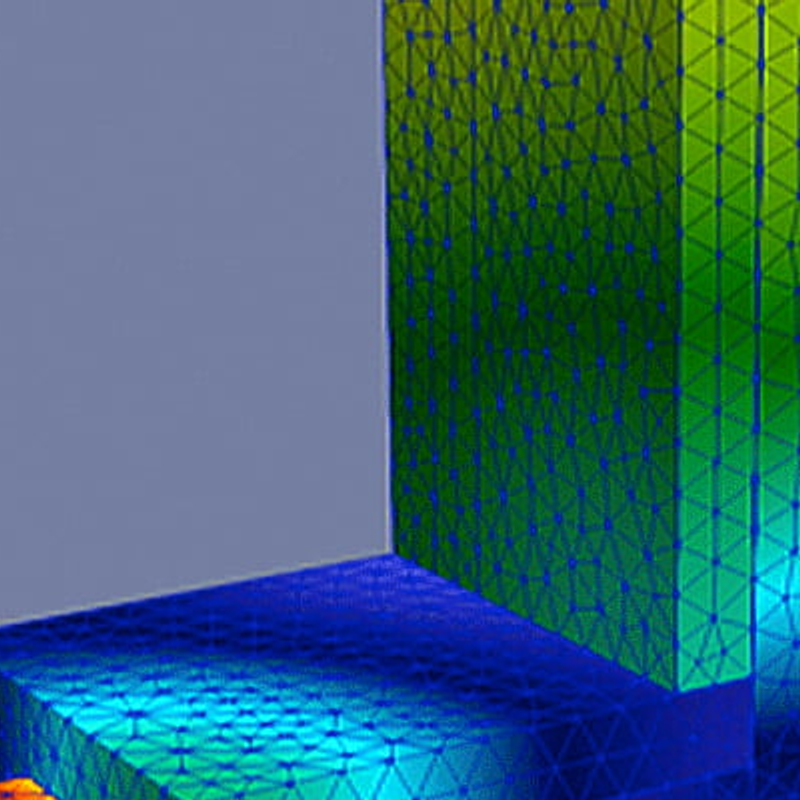

3. Monte Carlo simulations setup and biasing

Monte Carlo simulations can require advanced biasing techniques to produce good results. We use our expertise to reduce simulation complexity and the simulation time.

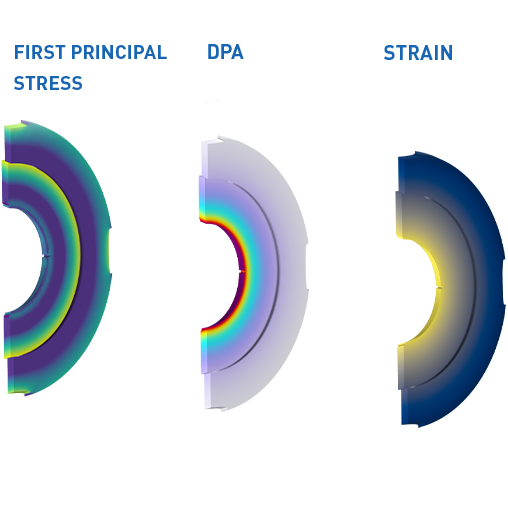

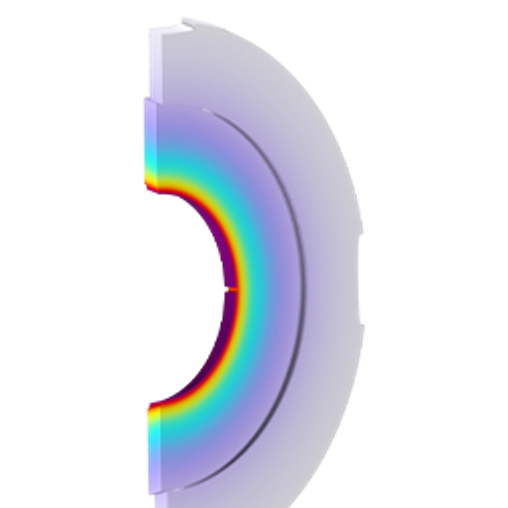

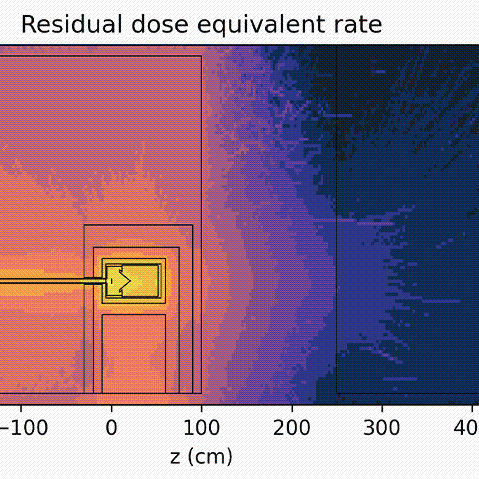

4. Assess dosimetric quantities for personnel. Both prompt and residual radiation are of importance and should be evaluated.

Using our expertise in Monte Carlo techniques and nuclear physics, we are able to design and verify an effective shielding strategy. Other metrics, such as heat load and activation of the target can also be considered and tested. All these aspects combined contribute to a safe and successful experiment, and are used to prove the feasibility of a nuclear process.

"making radiation visible"

As multiphysics engineer I use Monte Carlo methods to simulate radiation environments. Based on these results, both prompt and residual dosimetric quantities can be evaluated. Moreover, designing shielding systems in specific environments require a multiphysics approach, e.g. with regards to heat loads and material damage caused by the ionising radiation. All these factors contribute to the challenge of designing shielding systems to ensure human safety.

explore more cases.

Demcon multiphysics.

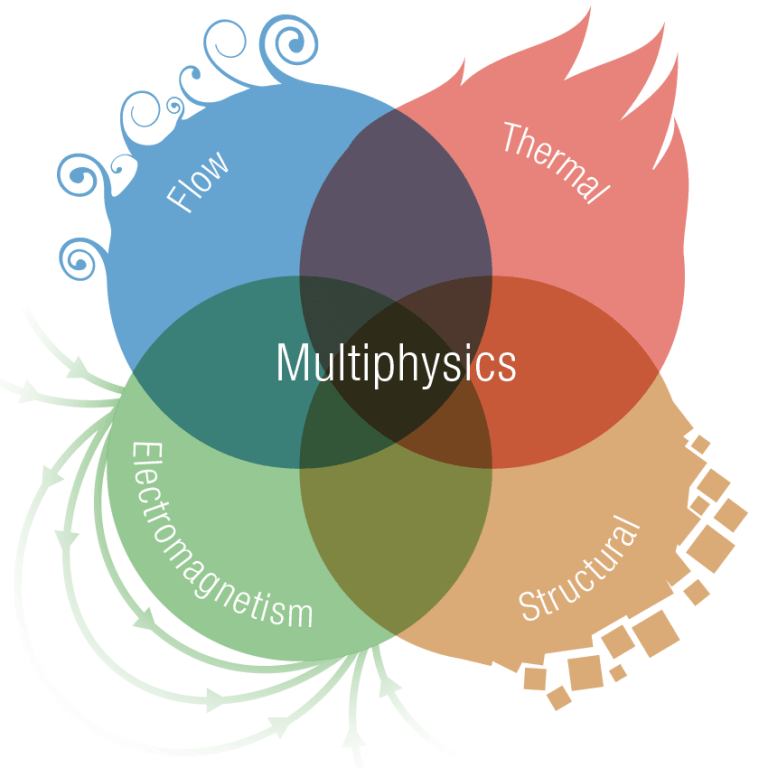

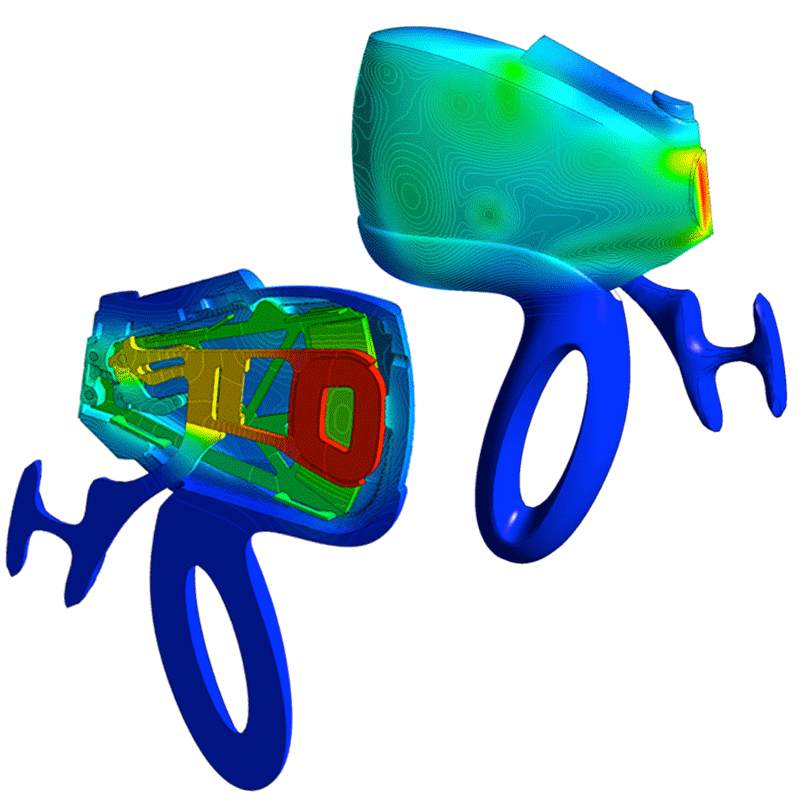

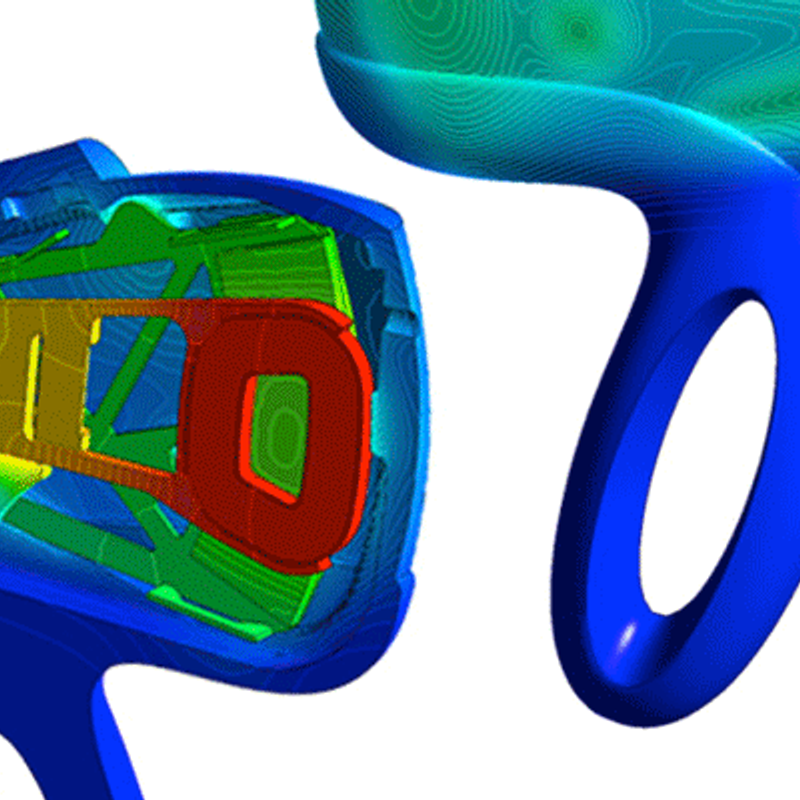

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.