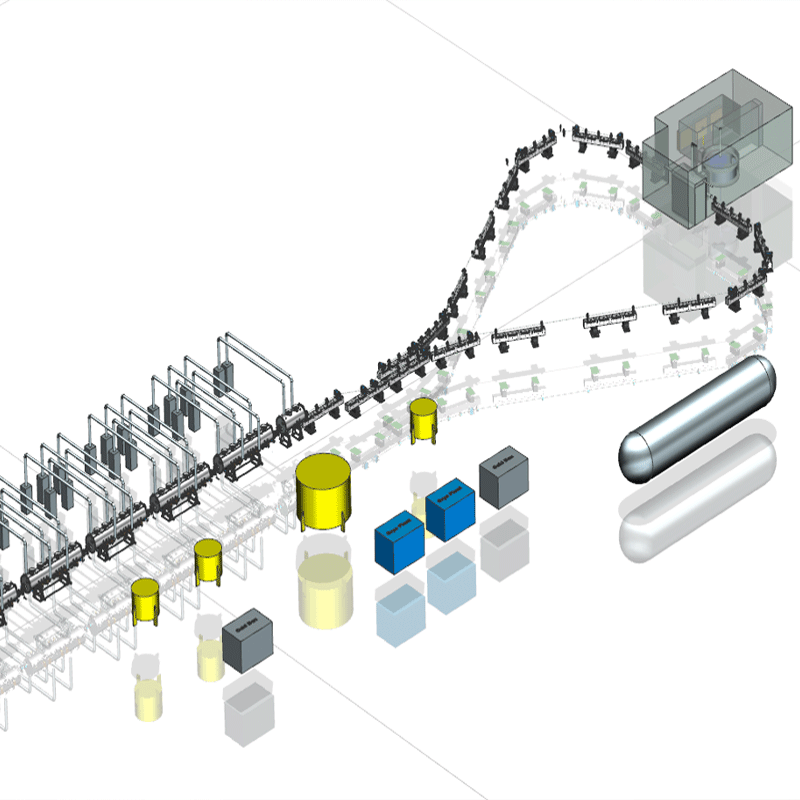

automating a bending process.

In a feasibility study a concept for aligning the two metal jaws was generated. A concept with a caliber guarantees limited spring back, but limits the throughput.

The challenge was to automate the bending without a caliber repeatedly having to be inserted between the jaws. This is to keep the treatment as easy as possible, and to prevent wear. Demcon opted for an optical solution using a standard smart camera from Festo.

The exact orientation of the jaws could be determined with image processing. A check was performed with a virtual caliber positioned between the jaws in a 3D reconstruction of the product. Casting faults could also be detected in the 3D reconstruction.

de uitdagingen die wij aangaan.

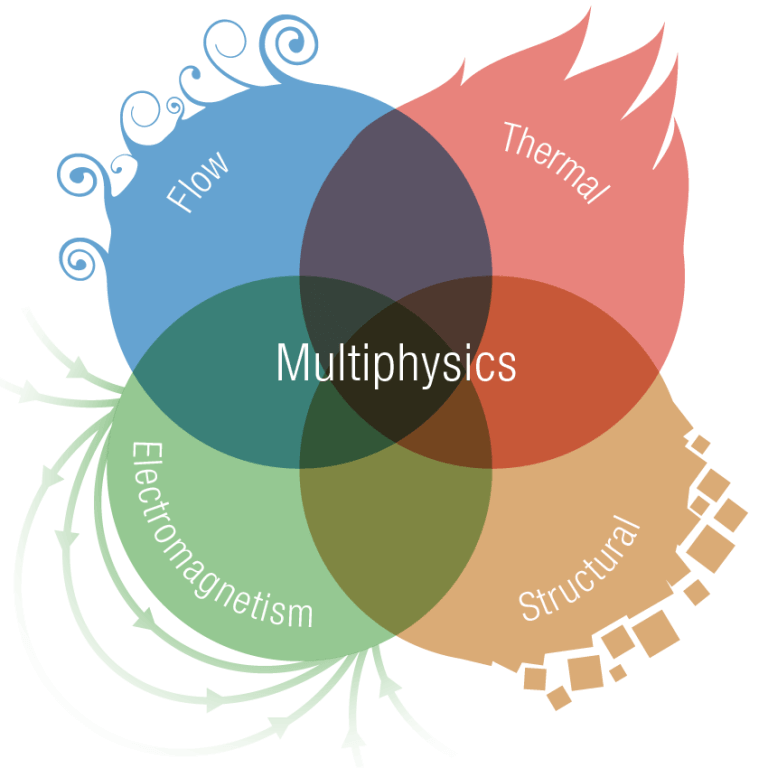

Demcon multiphysics.

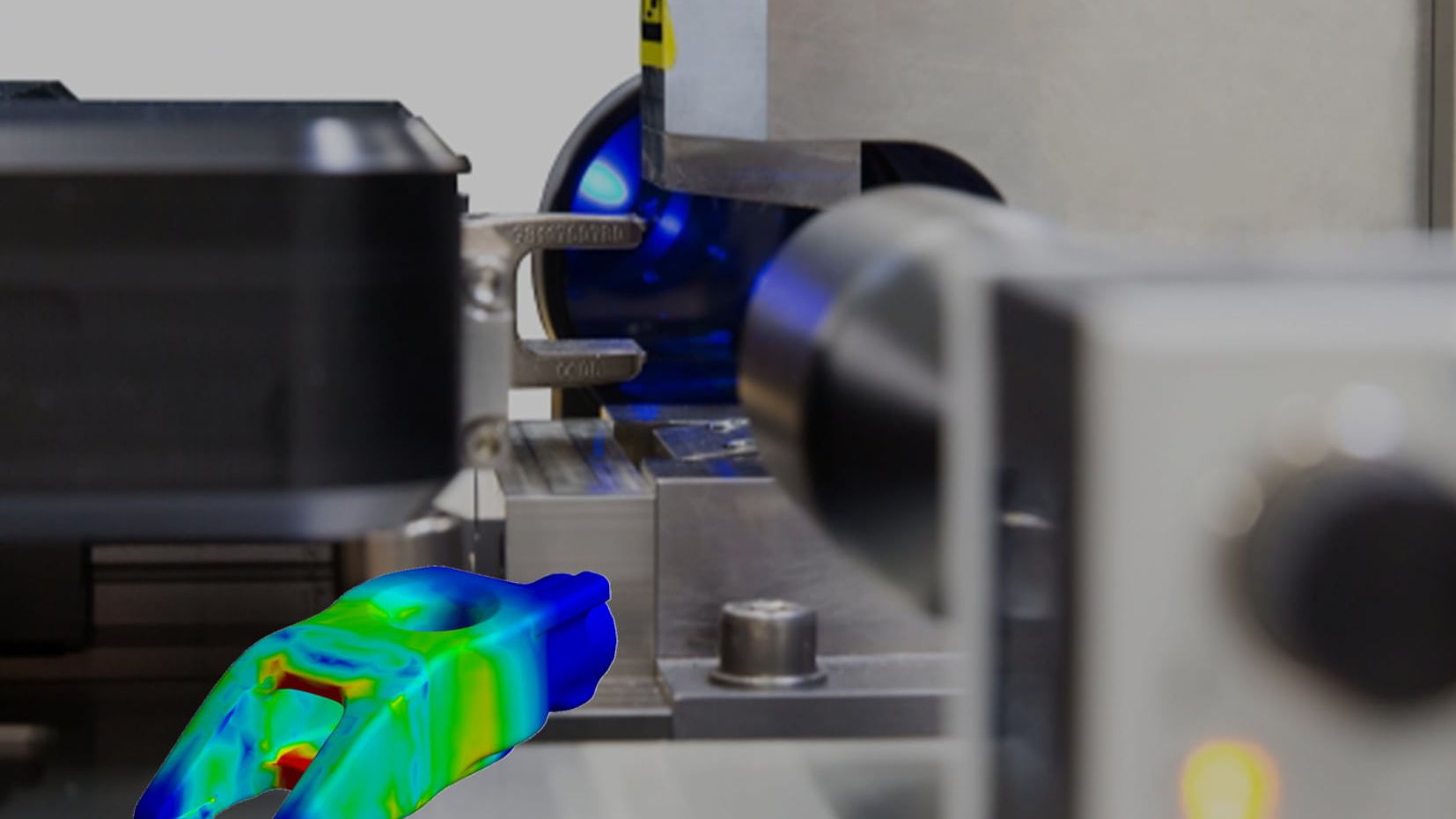

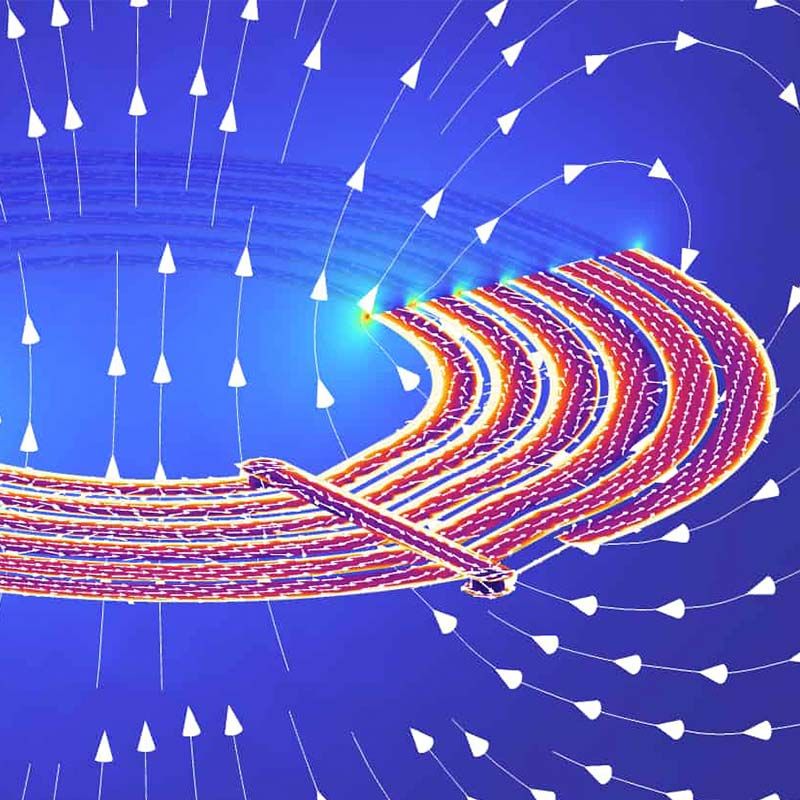

Demcon multiphysics is an engineering agency with high-end expertise in the area of heat transfer, fluid dynamics, structural mechanics, acoustics, electromagnetism and nuclear physics. We support clients from a wide variety of market sectors and help them achieve their goals in research and development with deep physical insights.

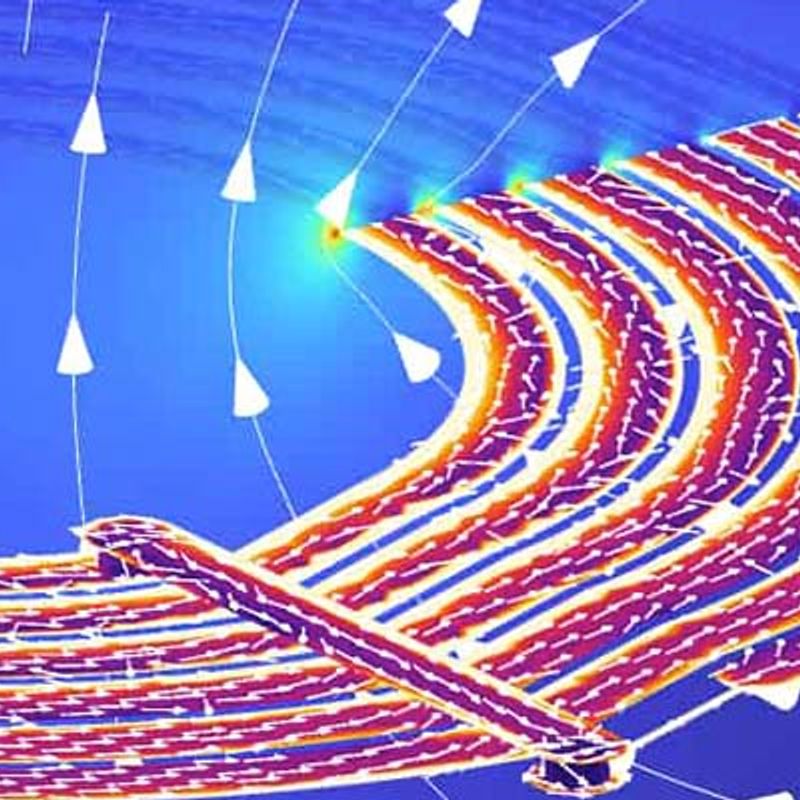

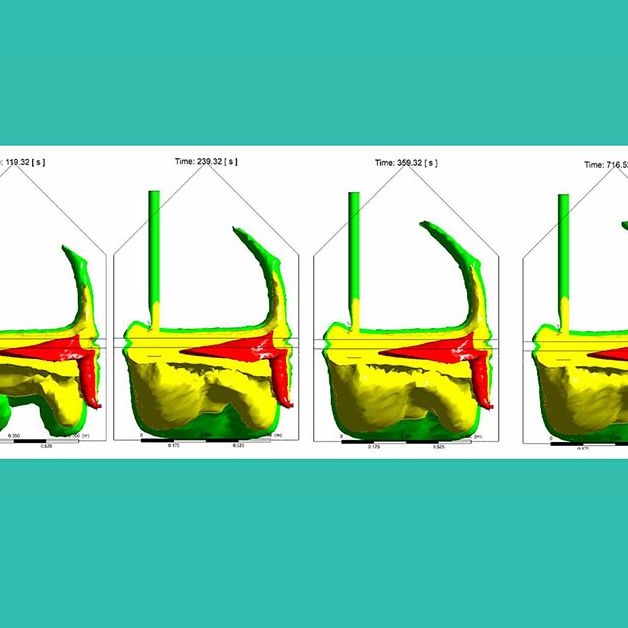

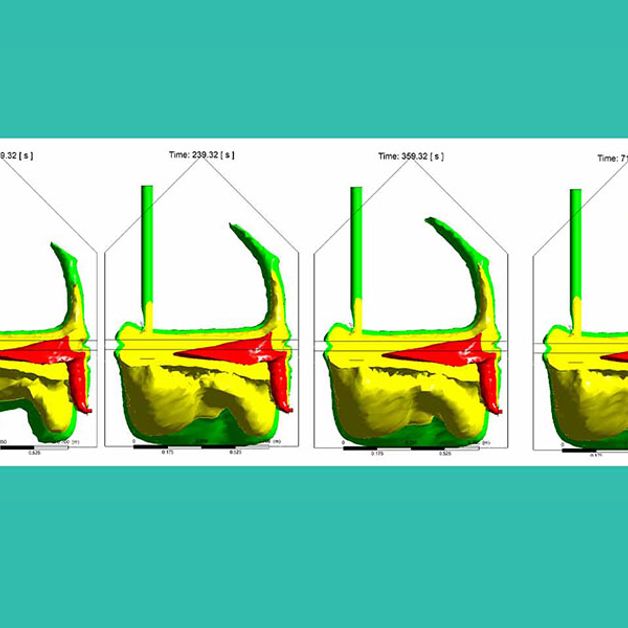

We combine fundamental physical knowledge from an analytical approach with Computer Aided Engineering (CAE) simulations tools from ANSYS, MATHWORKS, COMSOL, STAR-CCM+ and FLUKA to setup, execute, analyze and evaluate numerical simulations. The use of Computational Fluid Dynamics (CFD), Finite Element Analysis (FEM / FEA), Lumped Element Modelling (LEM), Computational Electromagnetics (CEM) and Monte Carlo simulations enables us to make a virtual prototype of your design. With these techniques we can simulate the fluid and gas flows, energy exchange, heat and mass transfer, stresses, strains and vibrations in structures and the interaction of electromagnetic fields with other physical aspects like heat generation. Simulation-driven product development increases the development efficiency and reduces the product development time. Our services can therefore fully support you in the designing phase, from idea up to prototype, from prototype to final design.